Samarium, a metallic element first discovered in a Russian mine in 1879, has proven to be an incredibly useful chemical reagent when combined with other elements. Named after the mineral samarskite in which it was found, which pays homage to Russian mining engineer Vassili Samarsky-Bykhovets, samarium has been instrumental in synthesizing molecules that have the potential to lead to the development of new pharmaceuticals.

Although samarium diiodide is the most common samarium reagent in use, consisting of one samarium atom and two iodine atoms, scaling up the production of this versatile reagent to industrial quantities has been a challenging task. According to Caltech graduate student Chungkeun Shin, the reagent’s air sensitivity requires fresh preparation right before any reaction. Additionally, the substantial amount of the reagent needed, even for small reactions, makes it impractical for running industrial-scale processes.

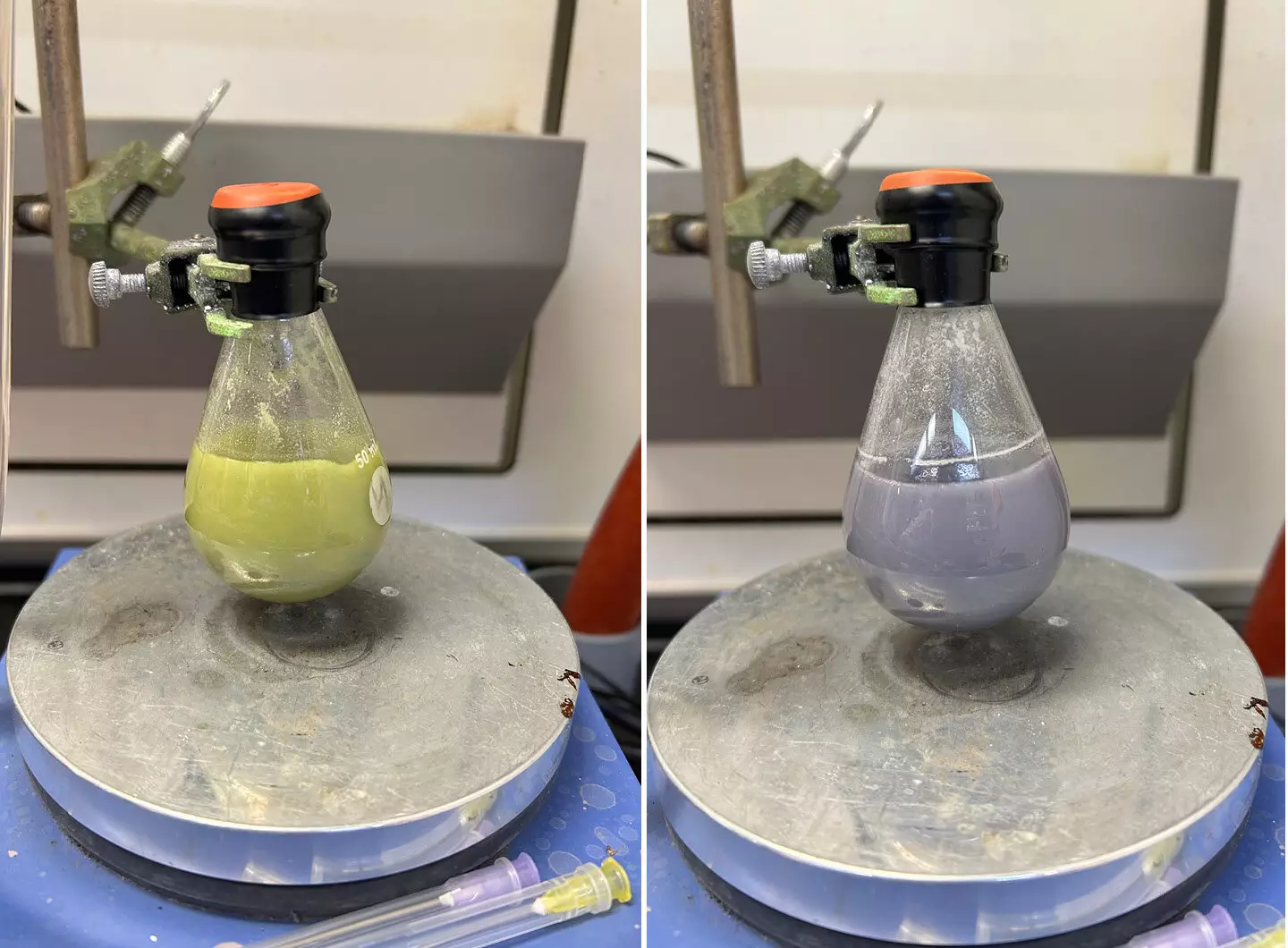

In a groundbreaking development reported in the journal Science on August 22, Caltech chemists have successfully tackled the challenge of scaling up the utilization of samarium diiodide reagent. By enabling the reagent to recycle itself during a single reaction, the excessive use of solvents and the preparation of fresh solutions are no longer necessary. The breakthrough now allows for the translation of interesting reactions from academia into industrial process development or discovery.

The pesky samarium-oxygen bond that previously hindered the industrial application of the reagent has now been addressed. Caltech graduate student Emily Boyd, alongside co-lead author Chungkeun Shin, has pioneered methods to break the inhibiting bond using mild acids, rather than harsh chemicals utilized in previous attempts. This innovation not only reactivates the samarium but also makes the process more suitable for large-scale chemical reactions.

Noteworthy collaborations between the Reisman and Peters labs at Caltech have further enhanced the research surrounding the samarium diiodide reagent. With a focus on nitrogen fixation, a crucial process for converting atmospheric nitrogen into essential compounds like ammonia, the labs are working on developing sustainable chemical reactions that can efficiently mimic the natural nitrogen fixation process carried out by bacteria.

The advancements made in the utilization of samarium diiodide reagent have opened up new possibilities for industrial chemistry applications. By overcoming challenges related to scaling up the reagent’s use and effectively recycling it in reactions, the door has been opened to a future where efficient and sustainable chemical processes can be developed on an industrial scale. The collaborative efforts of researchers are paving the way for transformative discoveries in the field of industrial chemistry.

With the breakthroughs achieved in the reactivation of samarium diiodide and its successful recycling in chemical reactions, the industrial chemistry landscape is sure to witness significant advancements in the coming years. The innovative methods developed by Caltech researchers have not only addressed longstanding challenges but have also set the stage for a new era of industrial chemistry marked by efficiency and sustainability.