As technology advances, the surge in electronic waste has become a significant concern for environmental sustainability. The disposal of e-waste poses a multitude of challenges, including not only the loss of valuable metals but also the environmental hazards linked to traditional recycling practices. The complexities surrounding e-waste necessitate innovative solutions, prompting researchers to explore more effective methods of metal recovery that mitigate environmental degradation.

Researchers at Rice University, spearheaded by Professor James Tour, have made groundbreaking strides in the recycling sector by unveiling a new technique designed to recover precious metals from electronic waste. This innovative methodology addresses the dual issues of resource recovery and environmental protection, effectively transforming the landscape of metal recycling. Their findings, published in the esteemed journal Nature Chemical Engineering, emphasize the technique’s potential to significantly reduce the ecological footprint associated with conventional recycling methods.

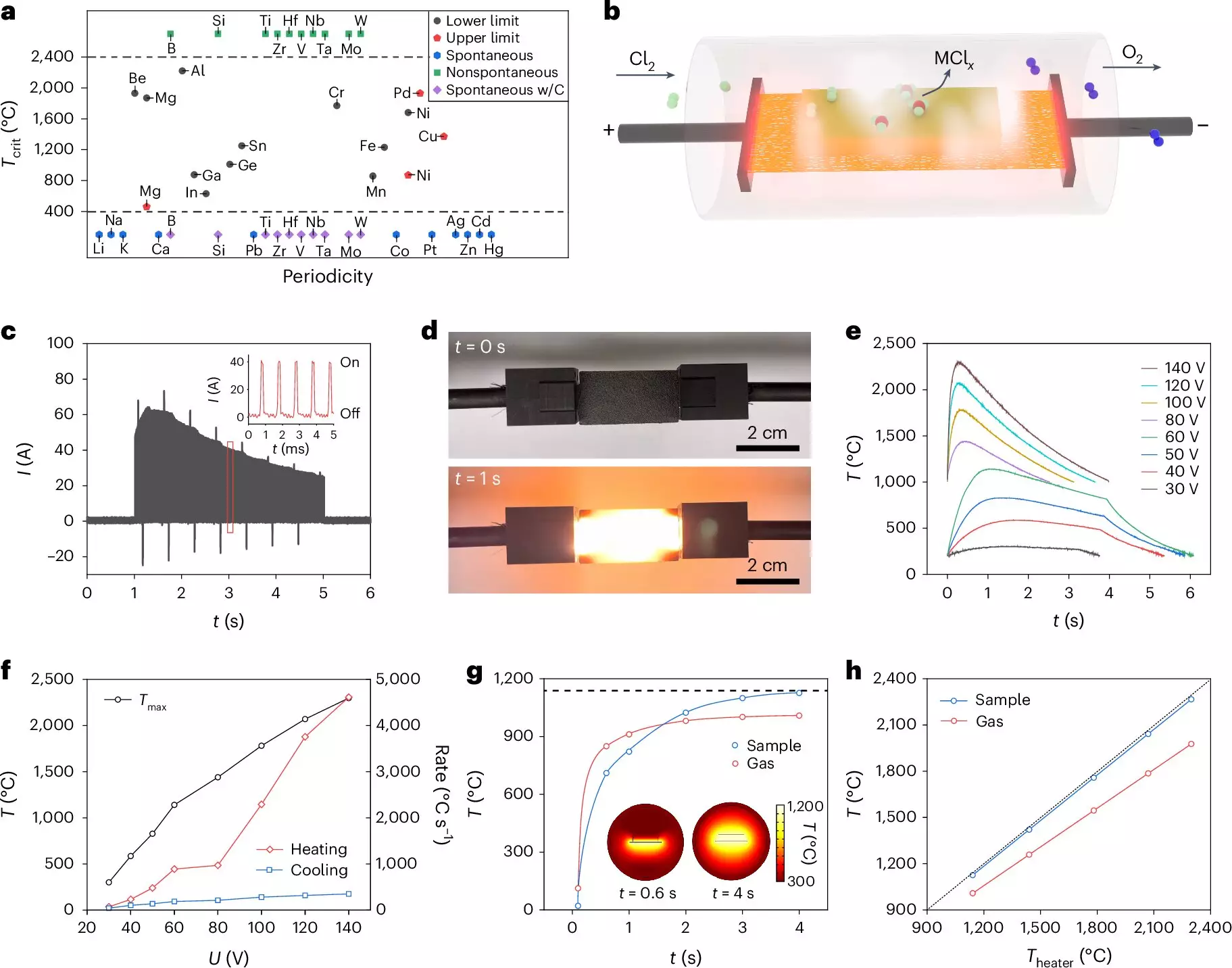

The method introduces an advancement on the flash Joule heating (FJH) process, facilitating rapid heating through the application of electric current. This technique not only elevates efficiency but also allows for meticulous temperature control, resulting in rapid separation of metals such as gallium, indium, and tantalum. Unlike traditional recycling approaches, which often rely on energy-intensive processes such as hydrometallurgy and pyrometallurgy, this new system minimizes the use of harmful acids and solvents, substantially lowering the risks of pollution.

The research team reported that their process yields over 85% recovery of metals with a purity surpassing 95%. This remarkable performance indicates a shift towards a more sustainable approach, contributing to decreased mining activity and its associated environmental repercussions, such as deforestation and water contamination. The ability to recover critical metals effectively serves to alleviate the burgeoning shortages faced by numerous industries while promoting a circular economy.

With a foundation laid for the recovery of key metals, the researchers aim to expand their approach to include lithium and rare Earth elements. This adaptability highlights the versatility of their technique and its capacity to meet diverse industrial needs. As the demand for these materials continues to rise in technology-driven sectors, ensuring a reliable and sustainable supply chain will be pivotal for ongoing innovation.

The pioneering work conducted by James Tour and his team represents a significant advancement in the quest for sustainable e-waste recycling. By revolutionizing the metal recovery process, this research not only addresses urgent environmental concerns but also fosters economically viable practices within the recycling industry. Such developments are crucial as global efforts continue to focus on mitigating the impacts of e-waste, paving the way for a greener and more sustainable future. The implications of this research may well extend beyond academia, inspiring industries worldwide to embrace greener practices, thereby enhancing their sustainability profiles.