Soft robotics has seen significant advancements in recent years, particularly with the development of Fabric-Based Soft Pneumatic Actuators (FSPAs). These innovative devices are designed to manipulate their shapes through inflation and deflation, providing a level of flexibility and safety that traditional robotics cannot match. As our understanding of materials and mechanics deepens, FSPAs offer promising applications across various settings, from wearable technology to robotic grippers and adaptable shelters. The challenge of designing these actuators effectively is immense, yet a recent study highlights the potential of Turing patterns, inspired by the work of noted mathematician Alan Turing, to transform the creation and functionality of soft pneumatic actuators.

The research team, hailing from Toyota Central R&D Labs, Inc. in Japan and Toyota Motor Engineering & Manufacturing North America, Inc. in the U.S., utilized Turing’s morphogenesis theory, which explains how complex patterns in nature emerge from a homogeneous state. Turing patterns, seen in nature in the form of stripes or spirals, arise through the interactions of two substances: one promoting growth and the other inhibiting it. This feedback mechanism leads to distinct and repeating patterns which, when applied to the surface design of FSPAs, enable controlled movement and deformation when pneumatic pressure is applied.

The addition of spatially oriented patterns allows for a more sophisticated and controlled manipulation of the actuator, thus advancing the field of soft robotics. By analyzing these Turing patterns, researchers have identified a unique approach that melds design principles from biology with the functionality of robotics.

Despite their advantages, creating FSPAs presents a variety of challenges, primarily due to the necessity of trial and error in material selection and configuration. Traditional soft pneumatic actuators typically rely on isotropic materials—those that exhibit uniform properties in all directions. While this simplicity can aid in the manufacturing process, it limits the actuator’s ability to deform precisely as desired. The quest for anisotropic materials, which possess directionally dependent properties, often results in inefficient design processes and prolonged development times.

The research team’s breakthrough lies in addressing these challenges through an automated optimization process that allows for the manipulation of fibrous material arrangements on an actuator’s surface. By employing advanced computational techniques, they streamline the design process, thus overcoming the trial-and-error pitfalls typical of conventional methods.

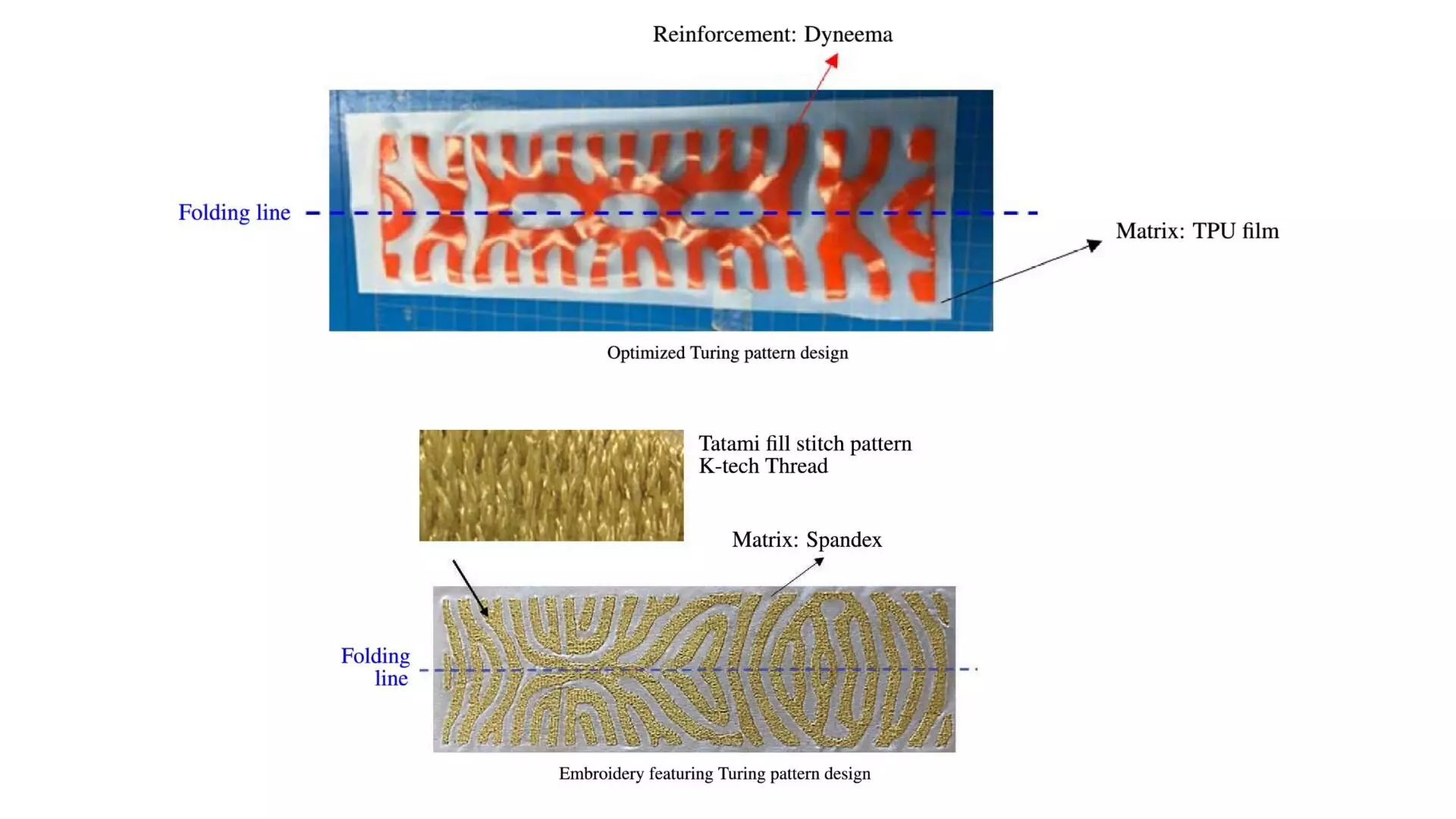

At the heart of the research are gradient-based orientation optimization methods that allow for precise control over the fabric’s material orientation. Utilizing the nonlinear finite element method, researchers were able to model and optimize how the fibers of the actuator’s material were aligned. The innovative design leads to Turing pattern textures that serve to facilitate desired deformation behaviors, forming the foundation for a new generation of FSPAs capable of advanced movements.

Furthermore, the team explored various fabrication techniques, including heat bonding and embroidery. By leveraging these methods, they were able to create complex patterns that correspond to the optimized material properties, ultimately resulting in more responsive and adaptable soft robotic devices. These new fabrication techniques not only yield better performance but also hold promise for scalable, cost-effective production methods.

A significant aspect of their research is the performance evaluation of their Turing pattern-based designs compared to traditional designs. Initial results revealed that the Turing pattern actuators performed equally or better than their classical counterparts, especially in particular motion tasks such as C-shaped deformations. This indicates a tangible advancement, as these new designs can achieve complex motions that were traditionally challenging while enhancing control over movements.

As the researchers look forward, the potential for integrating Turing patterns with cutting-edge materials—like shape-memory alloys or electroactive polymers—opens new avenues for the development of even more dynamic, versatile actuators. Alongside this, efforts to enhance manufacturing techniques such as 3D printing and automated fabric weaving underscore the vision for mass production capable of accommodating larger-scale applications.

The integration of Turing patterns into the design of FSPAs represents a significant leap forward in the field of soft robotics. By enabling more sophisticated control and enhanced functionality, this research contributes not only to advancements in robotic technology but also to broader societal impacts, such as improved rehabilitation devices, adaptable furniture, and accident-resilient robots that can safely interact with humans. The future of soft robotics is promising, fuelled by discoveries like those of the Toyota research team, which symbolize a new era of innovation driven by an interdisciplinary approach combining science, technology, and nature-inspired principles.