Small electric motors play a critical role in modern society, powering everything from household appliances to sophisticated automotive systems. These compact powerhouses are often found in devices such as refrigerators, washing machines, and power tools, alongside their indispensable roles in vehicles, where they contribute to essential functions such as cooling and fluid management. Although each motor has a seemingly minimal energy footprint, collectively, they present significant opportunities for energy savings and efficiency improvements. Given the growing emphasis on sustainability, optimizing the efficiency of these motors has become a paramount goal for researchers and engineers alike.

At the forefront of this initiative is the research team led by Annette Mütze at TU Graz’s Electric Drives and Power Electronic Systems Institute. Their project, the “CD Laboratory for Brushless Drives for Pump and Fan Applications,” seeks to harness and maximize the potential of small brushless electric motors. Through a combination of innovative design principles, modified control technologies, and cutting-edge manufacturing techniques, Mütze’s team has crafted integrated brushless drives that not only conserve energy more effectively but also operate more quietly than traditional motor designs.

This research acknowledges the nuanced balance between energy efficiency and acoustic performance. Mütze’s team has implemented design alterations, such as skewing and slotting the claws in claw pole motors—commonly used in lighting systems—to eradicate one of the more significant sources of motor noise known as “cogging torque.” These adjustments have reduced noise levels by an impressive 70%, resulting in smoother and quieter motor performance while also enhancing the overall user experience.

Shifting gears from mechanical to electronic advancements, Mütze and her team have introduced a novel approach to controlling the current supply in these motors. Traditionally, pulse width modulation (PWM) techniques regulate the current but require multiple switching operations that can lead to energy losses. Mütze’s innovative system simplifies this process by switching the drive on and off just once to achieve the desired rectangular current flow. This approach dramatically cuts down on switching losses, particularly evident at low current levels, thereby enhancing the overall efficiency of the motor.

One of the standout features of this new method is a notable reduction in the quantity of capacitors required on the motor’s circuit board. Fewer capacitors not only contribute to cost savings in manufacturing but also streamline the production process, making it more efficient.

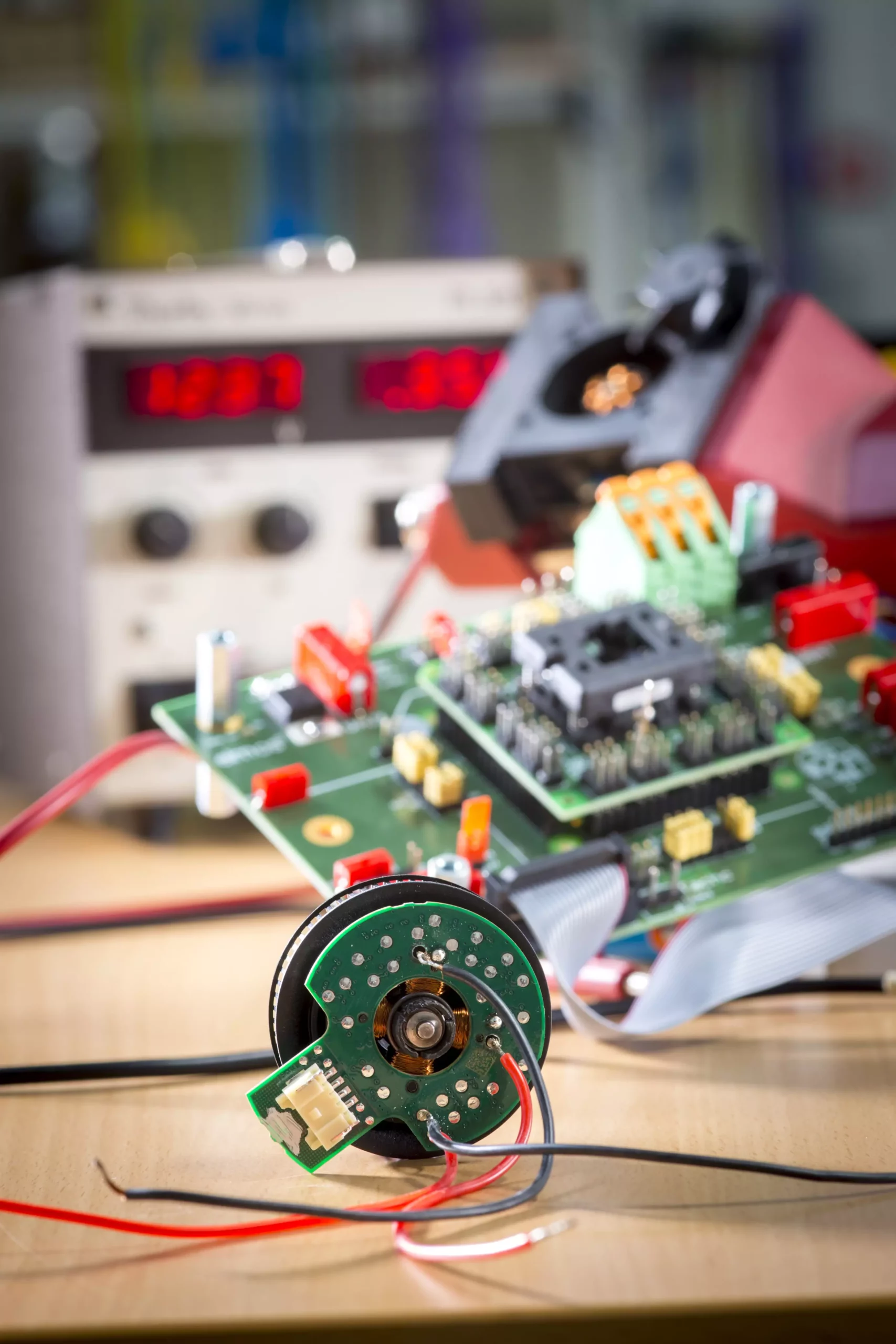

The research team’s embrace of printed circuit board (PCB) technology marks another exciting development in the field of electric motors. By designing the magnetic windings as printed circuit boards, they increase the automation potential within the production process, leading to a more streamlined fabrication system. Coupled with 3D-printing techniques for ferrite cores, this enables better magnetic flux management and makes the production of motors both efficient and cost-effective.

The implementation of ferrite-based magnets significantly reduces manufacturing expenses while enhancing performance, solidifying the market viability of smaller, highly efficient electric motors. This transition is particularly timely as the global push for greener technologies continues to accelerate, with electric motors playing an integral role in achieving ambitious energy reduction targets.

The advancements spearheaded by Mütze and her research team at TU Graz illustrate the potential for innovation in the field of small electric motors. By focusing on energy efficiency, noise reduction, and cost-effective manufacturing techniques, they are paving the way for the next generation of electric drives. As various industries seek to reduce their carbon footprints, these newly developed motor technologies could very well become standard, leading to a more sustainable and energy-efficient future. The remarkable strides made in this field serve not only the immediate need for efficiency but also underscore the importance of continuous innovation in our pursuit of a sustainable world.