The art of blacksmithing dates back to ancient civilizations, where early metalworkers discovered that manipulating metals through processes such as bending and hammering strengthened their integrity. This intuitive understanding laid the groundwork for what is known as work or strain hardening. This technique, integral to metallurgy, remains a cornerstone in modern manufacturing processes, influencing the strength of various components, from automotive frames to electrical infrastructure. However, until recently, the intricate mechanisms behind this vital process have eluded direct observation, hindering advancements in material design.

A recent research initiative led by a dedicated team at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has made significant strides in this domain. The findings, presented in the journal *Nature*, provide unprecedented insights into work hardening, revealing detailed processes that were previously hidden from view. Prof. Frans Spaepen, a prominent figure in the research, emphasizes the relevance of this discovery in the context of industrial deformation processes. The ability to observe the fundamental principles governing work hardening opens the door to potentially refining computer models that simulate these phenomena for improved accuracy.

Historically, the observation of work hardening in metals has posed significant challenges. The atomic structures involved are only visible through advanced electron microscopy techniques. Most studies have only been able to compare pre- and post-deformation structures, leaving a gap in understanding the real-time dynamics of the work hardening process. Previous research has established that defects, known as dislocations, play a crucial role in work hardening; however, the complex interactions among these defects have remained largely obscure. As Ilya Svetlizky, a contributor to the research, noted, unlocking the complexities of these interactions was pivotal to advancing the field.

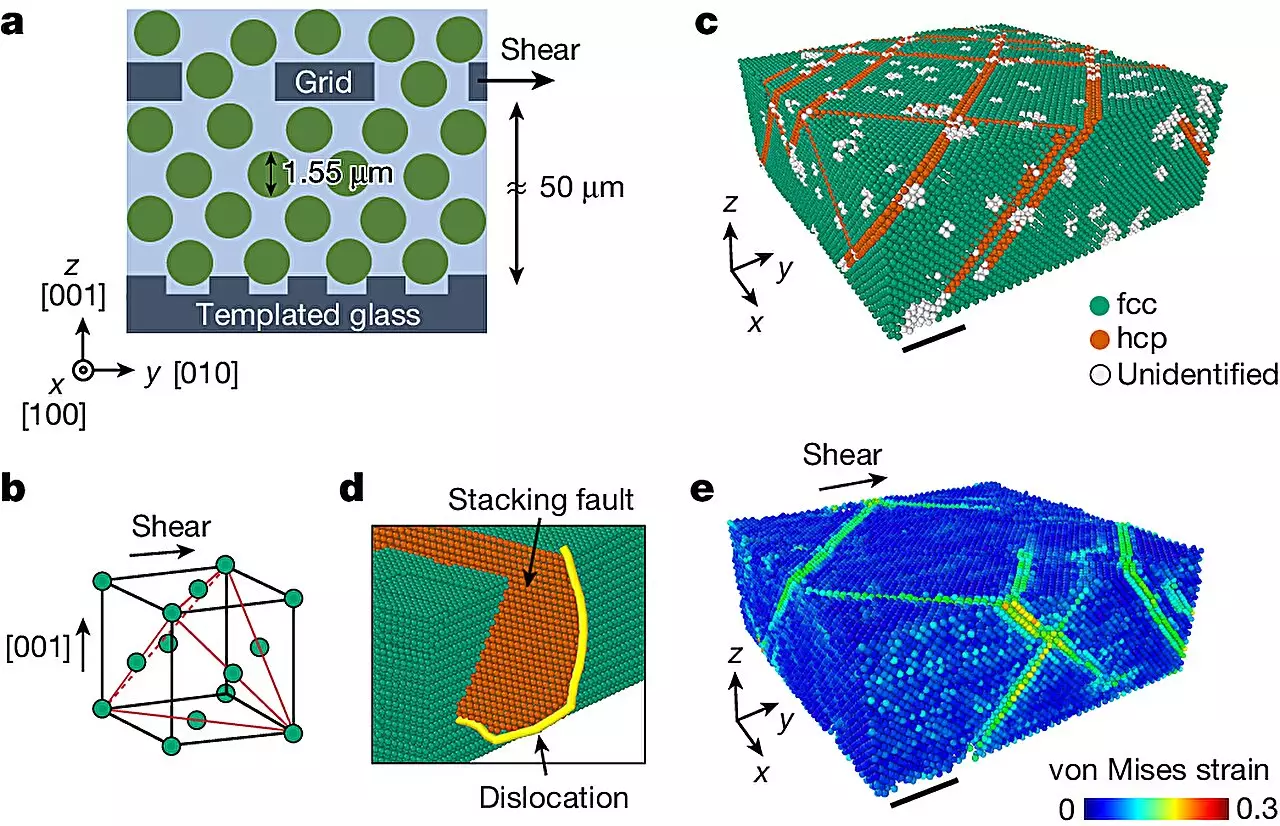

To bridge the gap in knowledge, the researchers turned their focus to colloidal crystals—structures composed of particles significantly larger than atoms. These crystals self-assemble into ordered formations under specific conditions, allowing researchers to model atomic behaviors effectively without the limitations of traditional metal studies. While colloidal crystals are incredibly soft compared to metals, the research team observed that they exhibited remarkable work hardening capabilities. This unexpected outcome highlighted the potential for new materials to surpass the traditional limitations seen in metals like copper and aluminum.

By applying strain to the engineered colloidal crystals and employing confocal optical microscopy, the team could quantify the behavior of individual particles under stress. Their results indicated that these soft materials evidenced significant work hardening phenomena, unexpectedly eclipsing the strengthening effects commonly associated with conventional metals. Seongsoo Kim, a graduate student involved in the investigation, remarked that the findings challenged prior assumptions about the relationship between particle interactions and material strength.

The implications of this research extend beyond just colloidal systems; the insights gained from studying these structures offer a universal understanding of work hardening applicable to a wide variety of materials. The revelations highlight the fundamental role of geometric arrangement and defect interactions in determining material properties. As David A. Weitz, another co-author of the study, pointed out, this research underscores the remarkable ability for soft materials to attain exceptional strength through work hardening dynamics.

The study contributes significantly to the broader narrative of material science, illustrating the intricate relationship between structure and strength. Such discoveries not only deepen our understanding of existing materials but also pave the way for the development of novel materials with tailored properties for specific applications. This breakthrough could herald a new era in material design, where the principles of work hardening inform innovative manufacturing techniques and lead to enhanced performance in engineering applications.

This landmark research on colloidal crystals not only enriches our comprehension of work hardening but establishes a framework for future explorations into the realm of material science. The journey from ancient blacksmithing to contemporary scientific inquiry encapsulates a fascinating evolution, one that promises continued advancements in the quest for stronger, more resilient materials.