Recent advancements by a team of bioengineers from the University of California, Berkeley, have ushered in a promising new class of adhesives designed with environmental sustainability at the forefront. This innovative adhesive polymer, detailed in the esteemed journal Science, marks a significant departure from traditional adhesive technologies, which often rely on hazardous materials and are specified for niche applications. Utilizing an electrophilic stabilizer, the team has successfully stabilized a naturally occurring fatty acid, thereby preventing its depolymerization and opening the door for broader applications.

The existing landscape of polymer adhesives is riddled with limitations. As highlighted by Zhibin Guan, a chemist affiliated with the University of California, Irvine, these adhesives are typically tailored to specific uses—such as wood bonding—which renders them unsuitable for general use. Moreover, most conventional adhesives pose significant risks to ecological systems, endangering both flora and fauna. As environmental concerns mount, the need for bio-based adhesives that minimize harmful impacts has never been more critical.

Harnessing the Power of Nature

In pursuit of a more versatile and eco-friendly option, the research team focused on polymers derived from alpha-lipoic acid (αLA), a naturally occurring fatty acid known for its biodegradability. By employing an electrophilic stabilizer, they effectively halted the breakdown of these polymers, thereby enabling the creation of a new lineup of adhesives that satisfy both performance and sustainability criteria. This strategy not only aligns with the principles of green chemistry but also addresses the escalating demand for versatile adhesive solutions across various sectors.

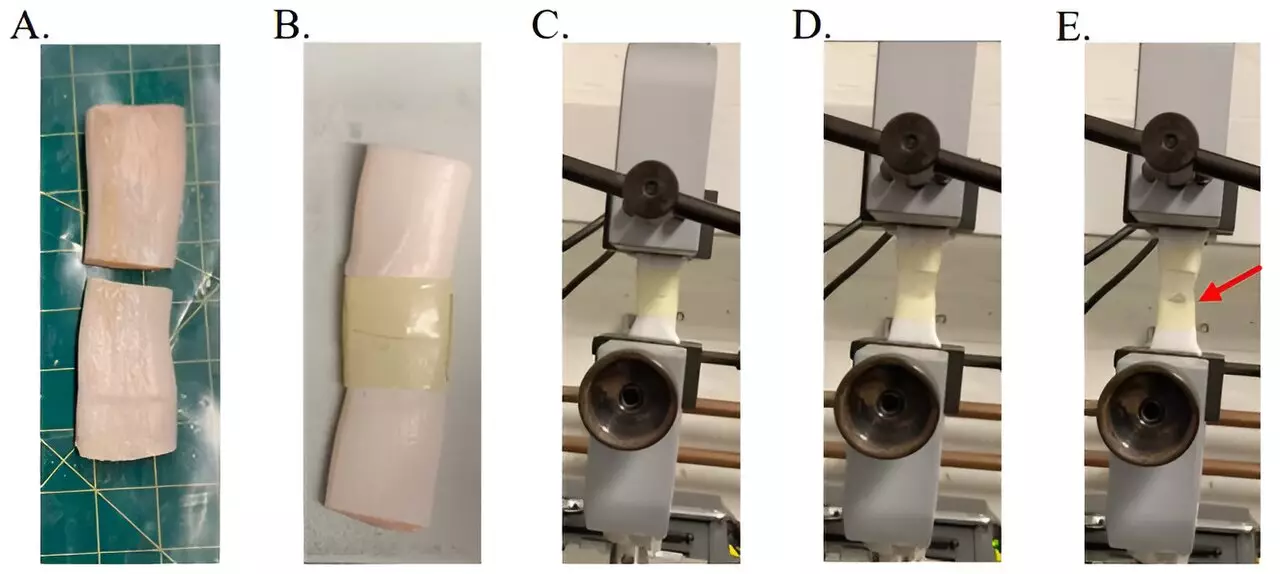

The newly developed αLA-based adhesives have undergone rigorous testing to evaluate their functionality across a diverse range of materials, including wood, metal, and biological tissues. Remarkably, these adhesives exhibit comparable strength to their petroleum-based counterparts, demonstrating their potential to replace more harmful options in both medical and non-medical applications. Notably, one variant of their pressure-sensitive adhesive exhibited tenfold greater peel strength than conventional alternatives, along with exceptional performance in both wet and dry environments.

Adding to the array of desirable attributes, the team’s adhesives also possess self-healing capabilities, making them particularly well-suited for medical uses where durability and reparability are paramount. Alongside these functional benefits, the research team devised an innovative closed-loop recycling system that allows old adhesives to be transformed into new ones with the introduction of water, significantly reducing waste. This system not only promotes sustainability but also encourages a circular economy model within the adhesive industry.

This groundbreaking work from UC Berkeley presents a compelling case for the future of adhesive technology. By combining natural resources with advanced engineering, the research team has set a new standard for products that prioritize both performance and ecological safety. As industries increasingly gravitate toward sustainable practices, these novel adhesive solutions could very well lead the way in transforming our approach to joining materials, emphasizing that environmental responsibility can harmoniously coexist with technological innovation.