In the field of material science, the correlation between the microstructure of materials and their resulting physical properties holds immense significance. Understanding this relationship is essential for enhancing material performance and developing innovative structural and functional materials. However, achieving this understanding is a complex task that necessitates advanced methodologies and tools. Recent research conducted by scientists at Lawrence Livermore National Laboratory (LLNL) marks a significant leap forward in this endeavor by introducing an integrated computational framework to analyze the properties of porous microstructures.

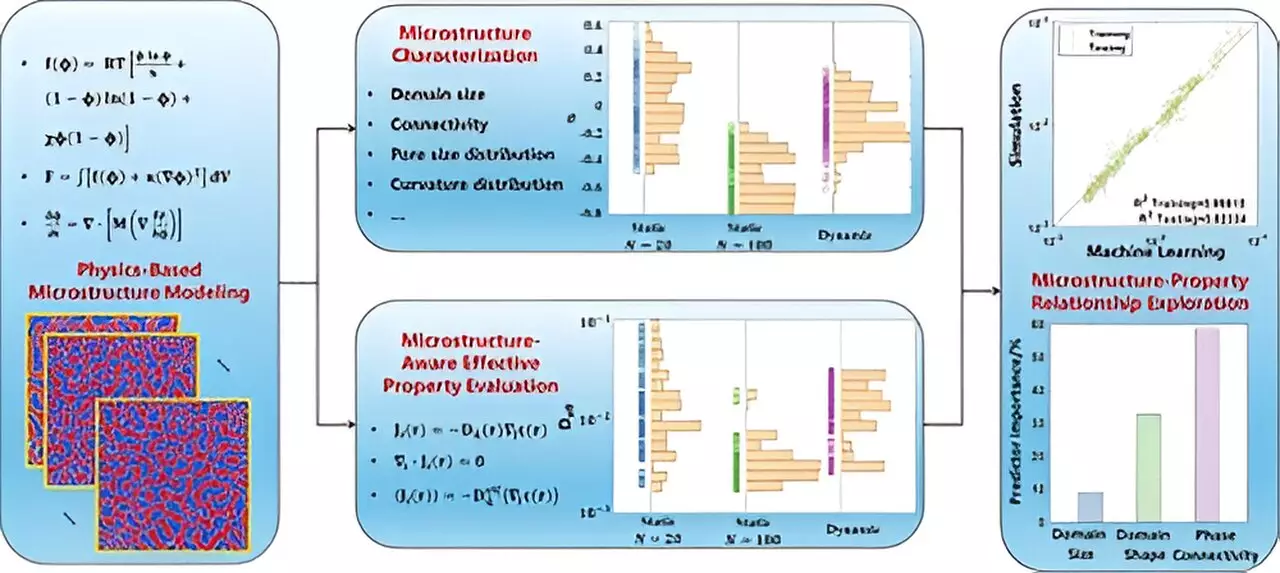

This novel framework integrates various computational techniques, enabling researchers to model microstructures accurately and assess their implications. As articulated by Longsheng Feng, the lead author of the study published in ACS Applied Materials & Interfaces, the framework combines microstructure modeling with machine learning tools and effective property evaluation. This holistic approach facilitates a deeper understanding of how different features within a microstructure impact a material’s performance. Specifically, the research focuses on polymer-based porous materials, which serve as a representative model system to explore the multifaceted interactions between microstructure and transport properties.

The innovative computational framework enables researchers to delve into polymerization dynamics and its effects on microstructure characteristics. By examining variables such as domain size and pore size distribution, the team can unveil how these features influence the transport properties of the materials. This exploration marks an important milestone in identifying the specific microstructural attributes that contribute to varying physical properties, providing a roadmap for future research and material design.

The implications of this research extend far beyond theoretical understanding; they pave the way for practical applications in designing advanced materials. As co-author Tae Wook Heo points out, the ability to discern the relationship between microstructure features and material properties can inform processing techniques. By tailoring specific microstructures, scientists can create polymeric porous materials optimized for various applications, including membrane technologies. This capability can revolutionize industries reliant on high-performance materials by enhancing their efficiency and functionality.

The work conducted by LLNL scientists represents a pivotal advance in our capacity to link microstructural features with their overarching properties. By leveraging a comprehensive computational framework, researchers gain a critical tool to navigate the complexities of material performance. As this field continues to evolve, the insights obtained from such studies will undoubtedly inform the design of next-generation materials that are both efficient and tailored for specific applications. This research not only enriches the academic discourse surrounding material science but also holds the promise of transformative developments across numerous technological sectors.