In an exciting development in the realm of additive manufacturing, engineers from the University of California San Diego have unveiled a novel 3D printing technique that promises to revolutionize how we create solid structures. This innovative approach utilizes a straightforward polymer ink combined with saltwater, offering a sustainable alternative to traditional materials manufacturing processes. Published in the esteemed journal *Nature Communications*, this study highlights a method that not only mitigates environmental impacts but also simplifies the fabrication process.

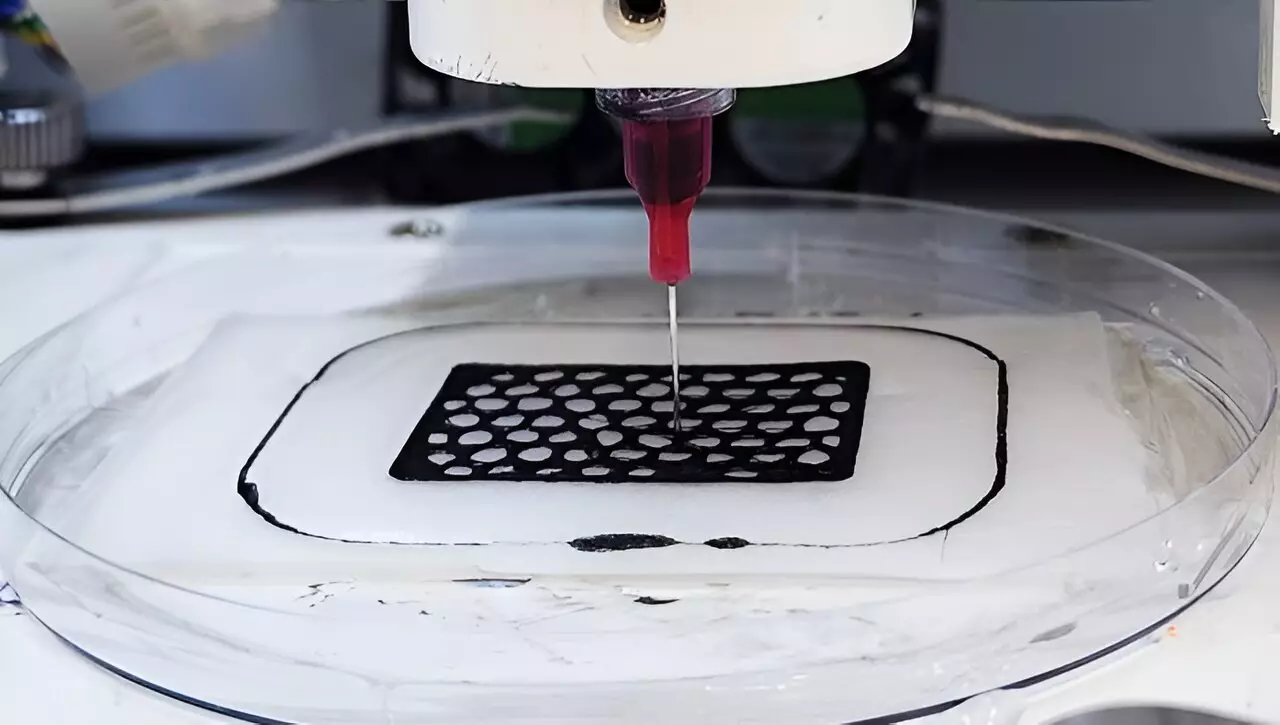

At the core of this new technique is a liquid polymer known as poly(N-isopropylacrylamide) or PNIPAM. When extruded through a fine needle and introduced into a calcium chloride salt solution, the polymer undergoes an instant transformation, solidifying upon contact with the saline medium. This remarkable phenomenon is a result of the “salting-out effect,” where salt ions attract water molecules from the polymer solution, triggering the aggregation of hydrophobic polymer chains into a dense solid. This process is conducted under ambient conditions, eliminating the need for energy-intensive processes that are the hallmark of traditional polymer solidification methods.

The significance of this breakthrough extends beyond its novel mechanics. Traditional polymer processing often involves harsh chemicals, high temperatures, and significant energy inputs, all of which can pose environmental risks. In stark contrast, the UC San Diego method stands out as it employs benign materials and operates at room temperature, significantly reducing its environmental footprint. Senior author Jinhye Bae emphasizes that this approach allows for the creation of solid structures without the associated costs of traditional methods, making it an appealing choice for sustainable manufacturing practices.

Another compelling aspect of this technique is its reversibility. The solid structures produced can be readily dissolved in fresh water, allowing the PNIPAM ink to be recovered and reused for future printing applications. This feature not only promotes efficient material usage but also introduces a practical pathway for recycling polymer materials. Bae points out that this contributes to a broader vision wherein eco-friendly recycling practices become integral to polymer manufacturing technologies.

The versatility of the method is further underscored by the researchers’ ability to print structures incorporating additional materials. For instance, they successfully created an electrical circuit from PNIPAM mixed with carbon nanotubes capable of powering a light bulb. The dissolution capabilities of these printed circuits suggest immense potential for developing water-soluble electronic components, reducing electronic waste, and paving the way for more sustainable electronics.

This innovative 3D printing technique from UC San Diego not only simplifies the manufacturing process but also promotes eco-conscious practices within the industry. By leveraging the unique interactions between a polymer ink and saltwater, this method offers a glimpse into a future where sustainability and advanced manufacturing coexist. As researchers continue to explore the full capabilities of this technology, the prospect of transforming polymer production into a more efficient, recyclable, and environmentally friendly endeavor appears ever more attainable.