The quest for advanced materials has never been more critical, especially as humanity pushes the boundaries of exploration into extreme environments like space and the Arctic. Traditional materials like steel and aluminum, though robust in manageable contexts, falter under extreme temperatures and pressures. At around 2,500 degrees Fahrenheit, steel succumbs to melting, while aluminum’s strength deteriorates upon exposure to moisture and oxygen. These weaknesses highlight a pressing need for innovative alloys capable of withstanding the harshest conditions while maintaining structural integrity, which is paramount for our future endeavors.

Multi-Principle Element Alloys: A New Frontier

Enter multi-principal element alloys (MPEAs). These futuristic materials consist of several elements in approximately equal proportions, offering a promising alternative to conventional alloys. MPEAs exhibit remarkable strength and toughness across a spectrum of temperatures, making them well-suited for extreme applications. They boast excellent resistance to corrosion and thermal stability, alongside unique functional properties beneficial for electronic and magnetic devices. As our industrial and scientific pursuits become increasingly ambitious, the emergence of MPEAs represents a beacon of hope for engineers and researchers alike.

Advancements from Johns Hopkins Applied Physics Laboratory

Recently, researchers at the Johns Hopkins Applied Physics Laboratory (APL) have made significant strides in the design and synthesis of MPEAs. Their innovative approach centers around the creation of complex microstructures that yield meaningful compositional data from only a handful of samples. This level of efficiency is critical in today’s fast-paced scientific environment, where time and resources are often limited. By analyzing alloy phases—distinct materials formed under different heating and cooling conditions—the team can effectively link the material’s mechanical properties to its composition.

In a groundbreaking study published in the journal “Data in Brief,” the APL team introduced a novel design capability that allowed for the synthesis of 17 unique MPEA compositions. Morgan Trexler, APL’s program manager for the Science of Extreme and Multifunctional Materials, emphasized the challenge of MPEA design, as minor compositional changes can lead to vast differences in material properties. This new capability not only streamlines the research process but also accelerates the pace of material discovery, allowing for a broader spectrum of potential applications.

Bayesian Optimization: Sifting Through Alloy Possibilities

The success of this advanced alloy design project is further magnified by the collaboration with researchers Paulette Clancy and Maitreyee Sharma Priyadarshini from the Johns Hopkins Whiting School of Engineering. Utilizing a physics-informed Bayesian optimization algorithm known as PAL 2.0, the team can efficiently analyze combinations of alloying elements, drastically reducing the time needed to identify promising MPEA candidates. Unlike most deep-learning approaches that require extensive databases, PAL 2.0 generates insightful recommendations even from a limited dataset of around a dozen points. This innovative closed-loop cycle ensures that every iteration brings the team closer to optimal outcomes in material performance.

The Iterative Process of Discovering Superior Alloys

The researchers have now entered their third iterative cycle, demonstrating continuous improvement in their alloy portfolio. Initial attempts resulted in suggestions for alloys that were costly or unfeasible to produce. However, through successive iterations and the incorporation of experimental findings, the team has successfully identified alloys with hardness measurements exceeding previous standards. This methodical approach underlines the importance of agile and responsive research protocols in materials science.

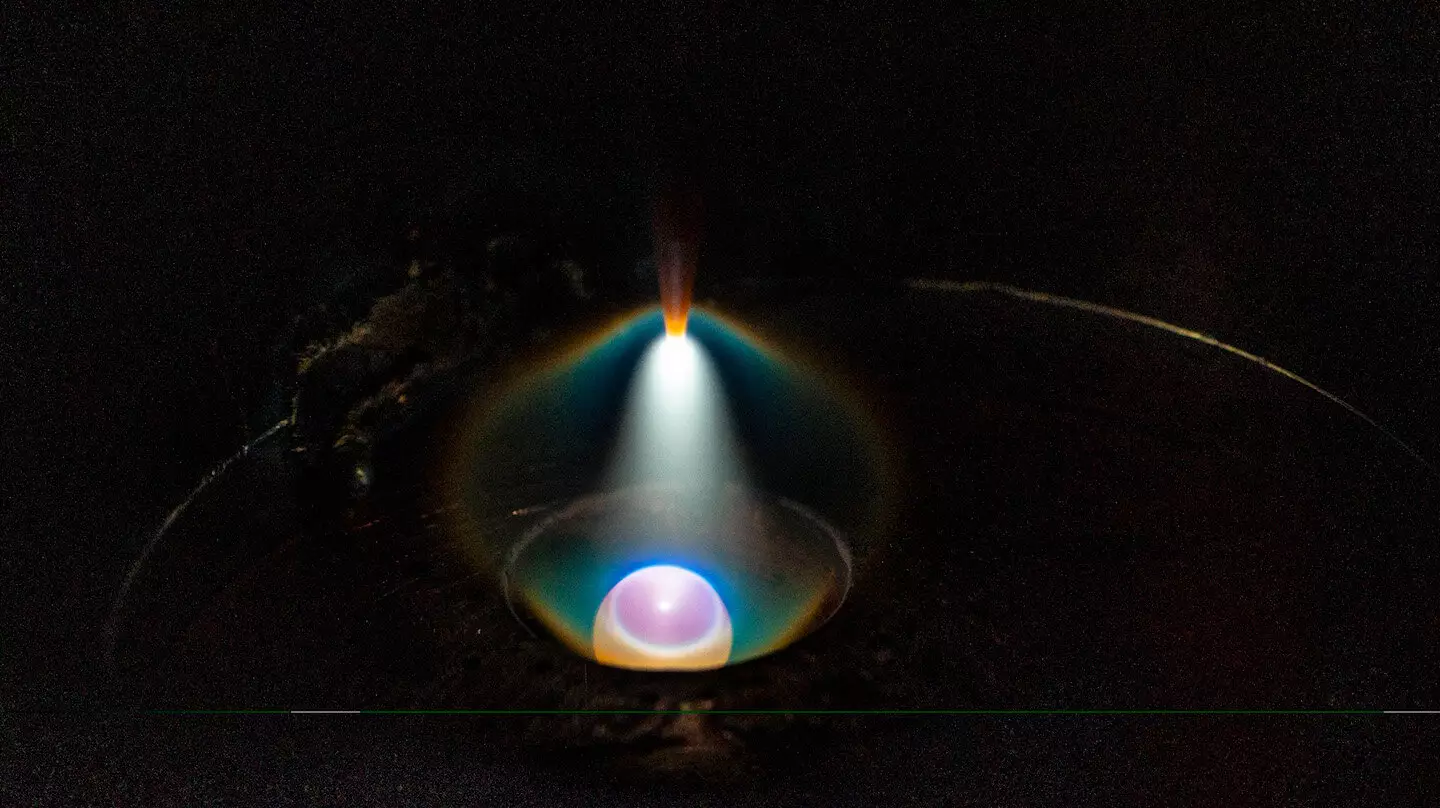

The fabrication process employs arc melting, a technique that utilizes electric currents to melt metals efficiently, allowing for rapid development of varied compositions. “When the alloy is melted, it essentially creates dozens of different materials with different chemical compositions all within one sample,” explains Eddie Gienger, a materials scientist at APL. This diverse generation of compositions facilitates a broad exploration of physical properties, propelling the research forward.

Integration of Advanced Characterization Techniques

Further enhancing this innovative alloy development are cutting-edge characterization techniques. The integration of scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and nanoindentation provides a comprehensive view of the materials’ microstructures and mechanical behaviors. Such technological synergy enables the research team to glean insights into how specific compositions influence material performance across different phases. This comprehensive framework not only helps uncover new materials but also informs subsequent experiments.

The research has generated extensive databases, comprising over 7,000 unique data points linked to 17 distinct MPEA compositions. These insights solidify a pathway for future alloy design, emphasizing the potential for engineered materials to meet specific mechanical characteristics critical for their applications. The ambition behind these developments is not merely academic; it signifies a shift toward creating materials destined to withstand the rigors of modern exploration and industry.

In essence, the pioneering work at APL exemplifies a transformative approach to material science—opening doors to new possibilities in alloy development, making it an exciting frontier for both researchers and industries poised to benefit from engineered resilience in their materials.