A groundbreaking microscopy technique has emerged, profoundly changing our approach to material science and engineering. Researchers from the University of Sydney have introduced a novel method that enables the detection of minute alterations in the atomic-level architecture of crystalline materials. This advancement is particularly vital for industries focused on creating stronger, lighter components such as the aerospace sector, where the performance of materials directly impacts safety and efficiency. The study, highlighted in Nature Materials, opens the door for a better comprehension of fundamental material properties that influence everything from advanced steels used in ship hulls to specialized semiconductors in electronics.

Decoding Atomic Relationships

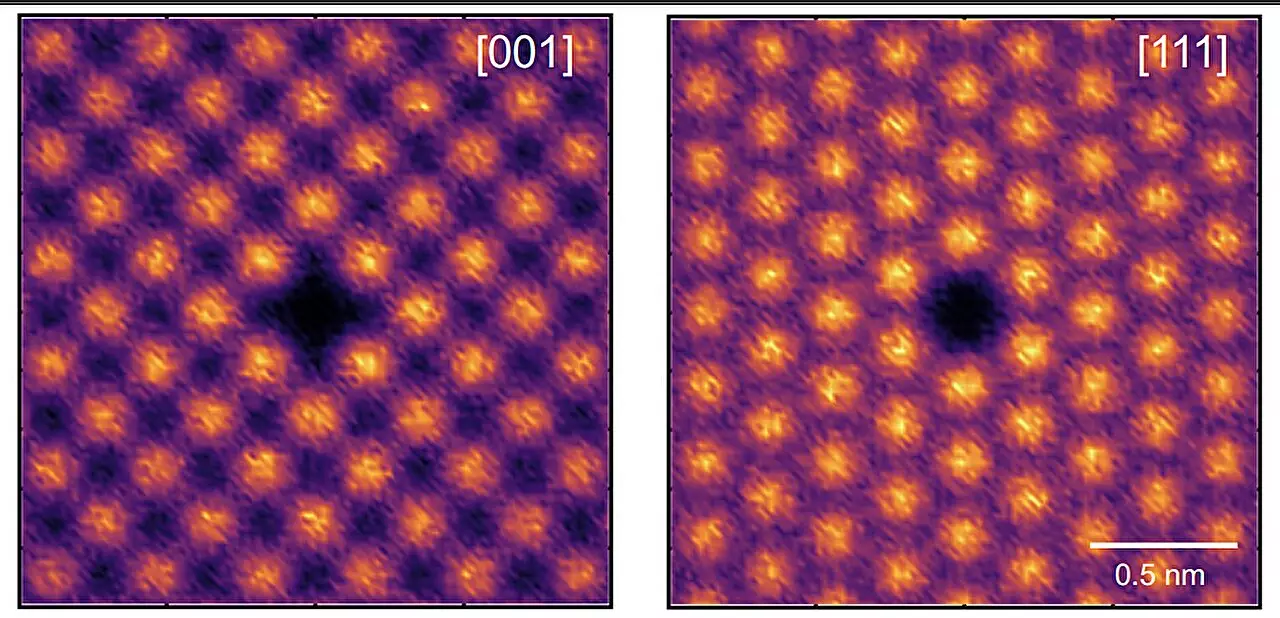

At the heart of this insightful research lies the innovative application of atom probe tomography (APT), guided by the expertise of Professor Simon Ringer and his team. APT’s utilization provides an invaluable look into short-range order (SRO), a phenomenon that characterizes the local atomic environment in crystalline structures. By analogizing SRO to a “materials genome,” the researchers unveil how the precise arrangement of atoms governs the properties of various materials, such as conductivity, magnetism, and structural integrity.

Traditionally, measuring SRO presents significant challenges due to the immensity of detail involved at the atomic level. Conventional microscopy lacks the resolution necessary to visualize atomic relationships. However, APT dismantles these barriers, paving the way for new developments in material innovations. The implications of this technique extend far beyond basic research; it ushers in the potential for tailored materials designed at the atomic level, ensuring they meet the desired specifications for functionality and safety.

High Entropy Alloys and Their Importance

The research primarily centers around high entropy alloys (HEAs), a class of materials that have gained extensive attention for their high-temperature strength and resilience. As the world increasingly turns to engineering solutions that withstand harsh conditions, HEAs have found applications ranging from jet engines to nuclear reactors. The study emphasizes that understanding SRO can significantly impact the performance of these materials under various processing conditions.

Professor Ringer elaborates on the global urgency in exploring HEAs, highlighting the demand for materials capable of enduring extreme environments. The fine-tuning of atomic arrangements via SRO can lead to better radiation shielding properties and improved engineering designs, forming a robust foundation for the future of engineering materials.

The Role of Data Science in Material Innovation

A striking aspect of the study is its integration of advanced data science methods alongside APT findings. By leveraging computational techniques to analyze data on SRO, the research team created a framework for modeling and predicting materials behavior with unprecedented accuracy. This dual approach not only enhances our comprehension of atomic structures but also empowers researchers to forecast how various materials will perform under specific stresses and conditions.

Dr. Mengwei He, a pivotal figure in this research, reflects on how these fresh insights transform material design. This new perspective allows for a detailed exploration of atomic architecture, where even the slightest alterations can yield significant enhancements in performance. It indicates a paradigm shift in material science, where intuition and foundational knowledge can be complemented with data-driven analyses.

Future Implications for Engineering and Beyond

The ramifications of this research go beyond immediate applications; they suggest a broader revolution in how material scientists think about the development of new alloys and other materials. This unprecedented ability to quantify SRO allows for a more systematic exploration of material properties, which could lead to an entirely new class of custom-engineered substances. The potential for optimizing materials for specific applications—where performance, weight, and cost must be meticulously balanced—becomes far more achievable.

Moreover, as industries continue to prioritize sustainability, the ability to design materials atom by atom aligns perfectly with global efforts to reduce waste and manufacture more efficient products. The knowledge gained from SRO enables engineers to create lighter, stronger, and more sustainable options that appeal to environmentally conscious consumers and industries alike.

Your Role in This Expansive Field

As we venture into this exciting phase of material science, it is essential for researchers, engineers, and industries to embrace these advancements. The discoveries surrounding SRO not only provide a deeper understanding of materials but also challenge us to rethink the design processes that underpin the engineering sector. There lies an electrifying opportunity for collaboration across disciplines, inspiring innovation that directly responds to society’s needs.

With researchers like Professor Ringer at the forefront, a bright future beckons, transforming our material landscapes into more robust, efficient, and sustainable entities that will define the next generation of engineering solutions. The journey toward material excellence has only just begun, and it promises to be as fascinating as the discoveries that await us in the microscopic world.