As electric vehicles (EVs) gain traction in the global automotive market, the pursuit of innovative energy storage technologies is becoming increasingly critical. One of the primary challenges these vehicles face is their limited range; drivers demand solutions that can sustain longer trips without compromising safety or performance. To address this, researchers are exploring the concept of structural batteries, which not only serve as energy reservoirs but also as integral components of the vehicle’s structure. This paradigm shift aims not only to enhance vehicle endurance but also revolutionize how we conceive energy storage systems.

Structural batteries represent a groundbreaking shift from traditional battery designs by embedding the energy storage capabilities directly into the framework of the vehicle itself. Unlike conventional batteries which are bulky and often adds weight, structural batteries aim to combine dual functionalities—acting as both a battery and a structural element. This integration has the potential to streamline manufacturing processes, reduce overall weight, and improve safety margins in vehicle design.

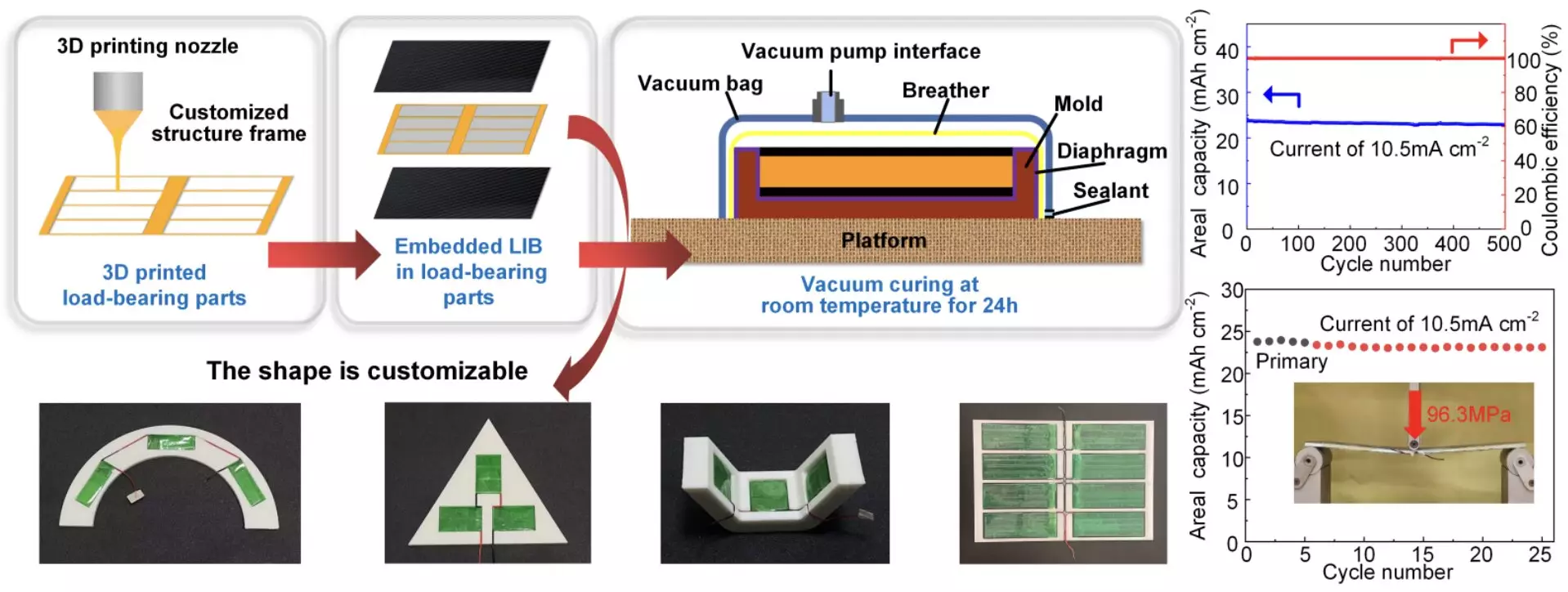

A recent study led by researchers from Shanghai University has unveiled a method that leverages advanced 3D printing technologies to fabricate high-performance structural batteries characterized by customizable shapes and dimensions. According to Yinhua Bao, the lead researcher on the project, these tailored designs offer a unique opportunity to create components that effectively balance energy storage with mechanical resilience.

3D printing has emerged as a vital tool in modern manufacturing, and its application in the production of structural batteries marks a significant milestone. The ability to create intricate designs with precision and speed allows researchers to optimize battery components for specific functions. In their study, the researchers focused on developing a decoupled framework that minimizes stress on the energy storage components, an approach that enhances their longevity and efficiency.

By utilizing high-performance materials in the fabrication of these batteries, the team aims to boost both energy density and cycle life significantly. The researchers demonstrated that it is possible to produce structural batteries with high load-bearing capacities while maintaining essential energy storage functionalities.

Despite their promising applications, many existing structural energy storage solutions come with significant limitations, including subpar energy densities and inadequate cycle stability. These deficiencies impair their practical deployment, particularly in demanding environments such as transportation. To combat these issues, the researchers at Shanghai University conducted extensive simulations to forecast potential failures during operational stress. By applying finite element software, they optimized the structural design to mitigate damage, an endeavor crucial to enhancing the operational reliability of structural batteries.

Another notable feature of the proposed structural batteries is their design philosophy: they are constructed with a distributed arrangement of battery cells. This configuration effectively minimizes the risk of total failure caused by localized damage, a common concern with traditional battery setups.

Initial tests on a fabricated composite structural battery have yielded promising outcomes, showcasing a high energy density of 120 Wh/kg and maintaining up to 92% of its charge after 500 operational cycles. The battery demonstrated remarkable resilience under mechanical stress, holding 98.7% of capacity at 80MPa and losing only a minimal percentage of performance per cycle. These impressive metrics suggest that the application of structural batteries could extend beyond just electric vehicles, finding utility in robotics or even unmanned aerial vehicles (UAVs).

The implications of developing viable structural batteries are far-reaching, touching various sectors from transportation to logistics. As researchers delve deeper into optimizing these batteries for mass production, the potential for their adoption in everyday applications becomes increasingly tangible. The next phase of research will likely explore cross-industry applications, paving the way for innovations that could reshape our energy consumption and storage practices.

The evolution of structural batteries through advanced fabrication methods like 3D printing holds immense promise for enhancing the efficiency of electric vehicles and various other applications. As research continues to push the boundaries of technology, the realization of fully integrated structural energy storage systems could pave the way for a future dominated by sustainable transportation solutions.