As summer temperatures soar, the quest for comfort under the sun becomes increasingly vital. From athletes on the field to families at the beach, the demand for cooling textiles is greater than ever. Recently, a groundbreaking development emerged from a team of researchers at the University of Massachusetts Amherst, who reported their success in creating a chalk-based coating that promises to revolutionize outdoor comfort. This article delves into the mechanisms, implications, and future prospects of this innovative technology.

The challenge of excessive heat during summer months often leads to discomfort and health concerns, particularly for those exposed to the sun for extended periods. Conventional fabrics typically absorb ultraviolet (UV) and near-infrared (near-IR) rays, contributing to an increase in temperature for wearers over time. Researchers—and consumers alike—have long sought materials that can mitigate these effects, ideally through a combination of heat deflection and the efficient dispersion of body heat.

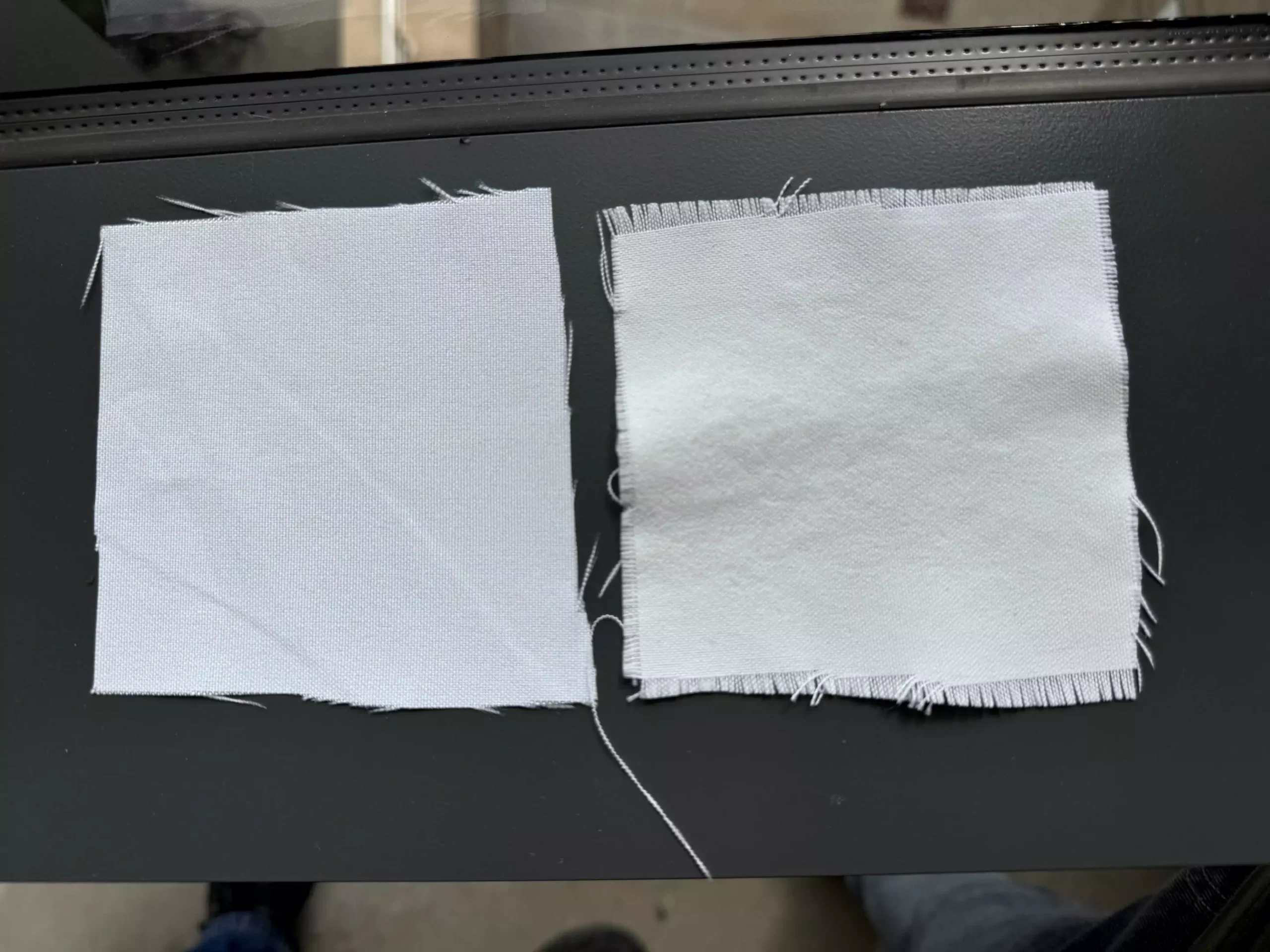

In the past, attempts to create such materials have revolved around complex fiber compositions and the inclusion of synthetic particles, such as titanium dioxide or aluminum oxide. While effective in theory, these high-tech fibers often come with a steep price tag and require environmentally challenging manufacturing processes. Thus, the need for a more sustainable and passive solution became evident, leading researchers to explore natural materials capable of generating similar cooling effects.

Evan D. Patamia, a graduate student involved in the research, and his team, under the guidance of chemist Trisha L. Andrew, developed a unique approach that leverages the natural cooling capabilities of chalk. Drawing inspiration from traditional plastering techniques used in ancient architecture to fend off heat, the researchers engineered a coating based on calcium carbonate—the primary component of chalk.

Utilizing a method known as chemical vapor deposition (CVD), which simplifies the typical multi-step process of attaching coatings to fabrics, they successfully developed a durable polymer layer on textiles. By adding barium sulfate to the mixture, which efficiently reflects UV light, the team created a composite that reflects light in both visible and near-IR wavelengths. The result? A fabric that not only withstands wear and tear but also actively cools the air beneath it by an impressive temperature differential of up to 8 degrees Fahrenheit—an achievement that could enhance outdoor experiences across various demographics.

During testing on a sunny day, the effectiveness of the treated fabrics was starkly evident. Researchers measured air temperature beneath the fabric and reported significant cooling—up to 15 degrees Fahrenheit in optimal conditions when compared to untreated counterparts. This demonstrates that the innovative chalk-based coating provides more than just a minor comfort boost; it establishes a notable difference that could significantly enhance individuals’ heat tolerance during high-temperature exposure.

The implications of this technology extend beyond mere comfort. Think of athletes striving for peak performance in glaring sunlight, laborers enduring long hours outdoors, or families taking their children to the beach. Creating breathable, effective cooling fabrics could transform outdoor activities into enjoyable experiences, fostering a conducive environment for physical exertion and leisure, even during the hottest parts of the day.

While the researchers have demonstrated success in laboratory settings, scaling up the manufacturing process presents its own set of challenges. Andrew is actively working with a startup focused on extending their CVD process to handle larger fabric batches, ultimately aiming to produce fabric rolls large enough for commercial use. This important next step will be critical in assessing the viability of the cooling fabrics on a wider scale and in various applications.

Additionally, ongoing studies will be necessary to analyze the long-term performance of the coatings in different environmental settings. The early results are promising, but ensuring the reliability and durability of adhesive properties, especially when subjected to wear and laundry processes, will be imperative.

The development of chalk-based cooling fabrics represents a pivotal moment in textile engineering, merging environmental sustainability with practical applications. As the world grapples with rising temperatures due to climate change, innovations like these hold the potential to improve comfort, promote health, and support outdoor activities across various sectors. By continuing to refine production methods and solidify their effectiveness, this research could lead to a new era in the battle against heat, proving that sometimes the best solutions lie in the simplest materials.