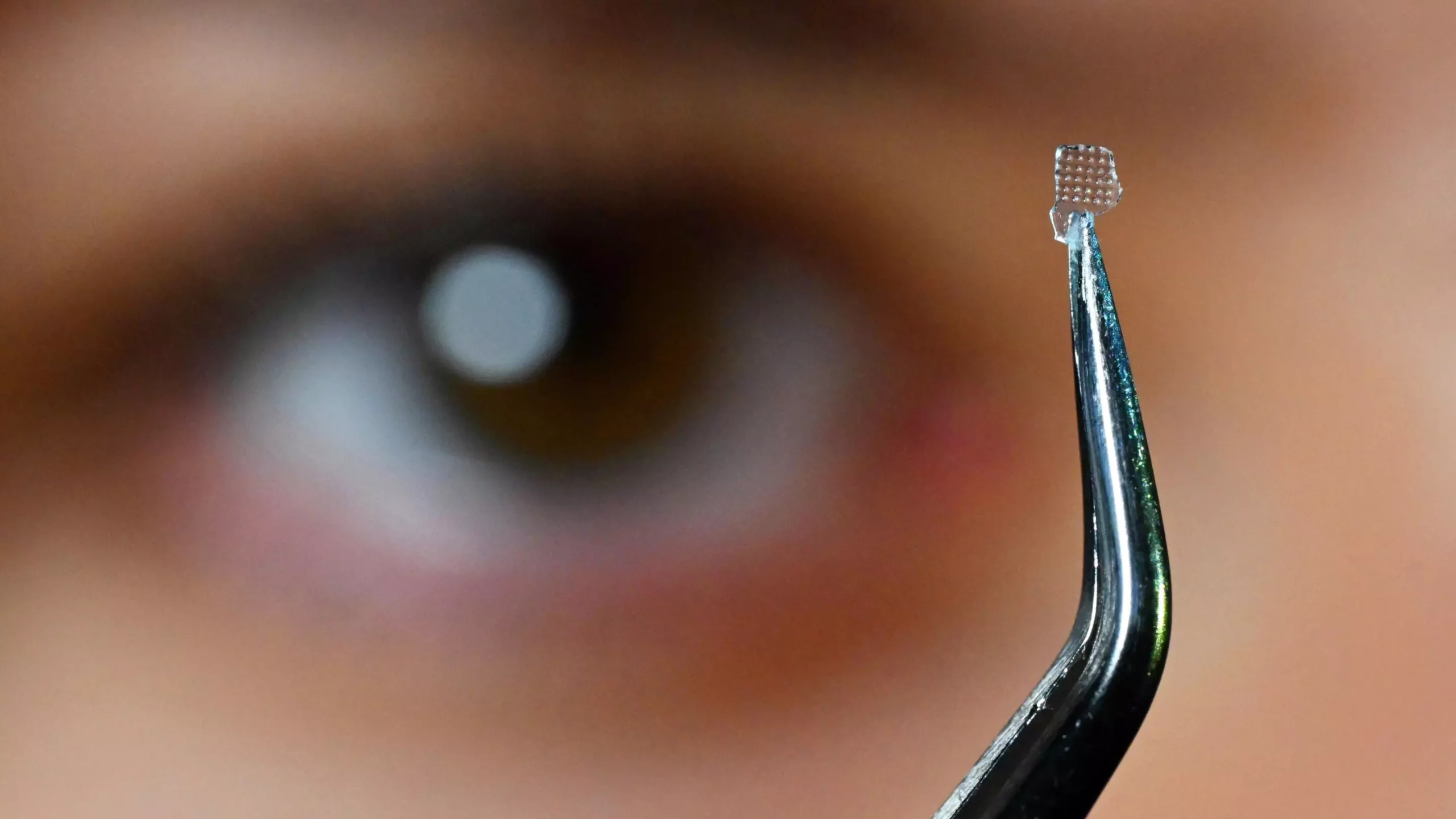

In an impressive display of innovation, researchers from the University of Jena have unveiled a groundbreaking micro-lens, which is not only diminutive in size but also exhibits remarkable adaptive optical properties. This small optical marvel, mere millimeters across, showcases a unique ability to alter its refractive behavior based on the presence of gaseous substances, a feature made possible by its advanced hybrid glass composition. Published recently in *Nature Communications*, this work highlights a significant advancement in materials science that holds immense promise for various applications in optical technology and beyond.

The Science Behind Adaptability

What distinguishes this new lens is its sophisticated molecular architecture—a three-dimensional lattice embedding cavities that can entrap gas molecules. Such an intricate design enables the material to communicate with its surrounding environment by changing its optical characteristics in response to gas absorption. The principle is straightforward yet profound: the lens modulates light refraction, depending on the gases it encounters. As Professor Lothar Wondraczek, a leading figure in glass chemistry, explains, this dynamic behavior marks a pivotal shift in the development of “multi-responsive materials.”

The process of marrying traditional glass-making techniques with the challenges posed by this innovative hybrid material was no small feat. Doctoral candidate Oksana Smirnova, the lead author, sheds light on the inherent difficulties in working with metal-organic frameworks, typically used for gas storage and separation. One significant hurdle remains their tendency to break down under heat, thereby complicating their practical application in shaping glass-like materials.

Innovative Manufacturing Techniques

The Jena team tackled these obstacles head-on, first focusing on the synthesis of highly pure material tailored for optical use. This was achieved by exploring optimal conditions for shaping the hybrid glass—a meticulous endeavor. Employing a blend of melting techniques and 3D printing, the researchers developed a process to create molds that can be pressed into virtually any form. Such versatility is particularly crucial when it comes to lenses, where even the slightest imperfections can significantly impact optical clarity.

By optimizing the manufacturing process for this lens shape, the team not only ensures precision but also opens the door for a plethora of applications extending well beyond mere optics. The potential applications are vast, from advanced computational systems utilizing optical circuits to the development of smart membranes that change function based on the gases they encounter.

A Vision for Future Applications

Imagine a world where optical devices are no longer passive components but rather interactive systems that respond intelligently to environmental changes. The implications of this research are monumental. By integrating multi-responsive materials, the Jena team envisions a future where gas-responsive optoelectronic devices can offer dual-feedback mechanisms. For instance, simultaneous exposure to light and specific gases could trigger distinctly programmed optical responses, creating a new arena for smart technologies.

This groundbreaking advancement could redefine not just the field of optics, but also have profound implications for environmental monitoring, gas sensing, and even health diagnostics. The innovative work led by the University of Jena may very well represent the dawning of a new age in materials science, paving the way for technologies that are not only intelligent but integrative, reshaping how we perceive and interact with the world around us.