As global interest in sustainable energy rises, the intermittent nature of renewable power sources like solar and wind remains a significant barrier to widespread adoption. The challenge lies not just in generating electricity but in effectively storing and delivering it to meet demand. This reality underscores the pivotal role hydrogen plays as a reliable energy carrier. Hydrogen can bridge the gaps in energy supply and demand when produced efficiently, particularly through water electrolysis. However, traditional methods are facing hurdles that researchers are eager to overcome.

Innovative Solutions from Leading Researchers

Recent collaborative research by a team from Pohang University of Science and Technology (POSTECH) and Seoul National University has introduced a promising catalyst that addresses these issues. Spearheaded by Professor Jeong Woo Han and involving experts like Professor Yong-Tae Kim and Dr. Sang-Mun Jung, the research published in *Advanced Functional Materials* has revealed a breakthrough that holds great potential for improving the durability of alkaline water electrolysis (AWE) systems. This new solution promises to optimize hydrogen production while tackling the issue of electrode degradation, particularly caused by reverse current fluctuations.

Understanding the Catalyst: The Role of Lead Coatings

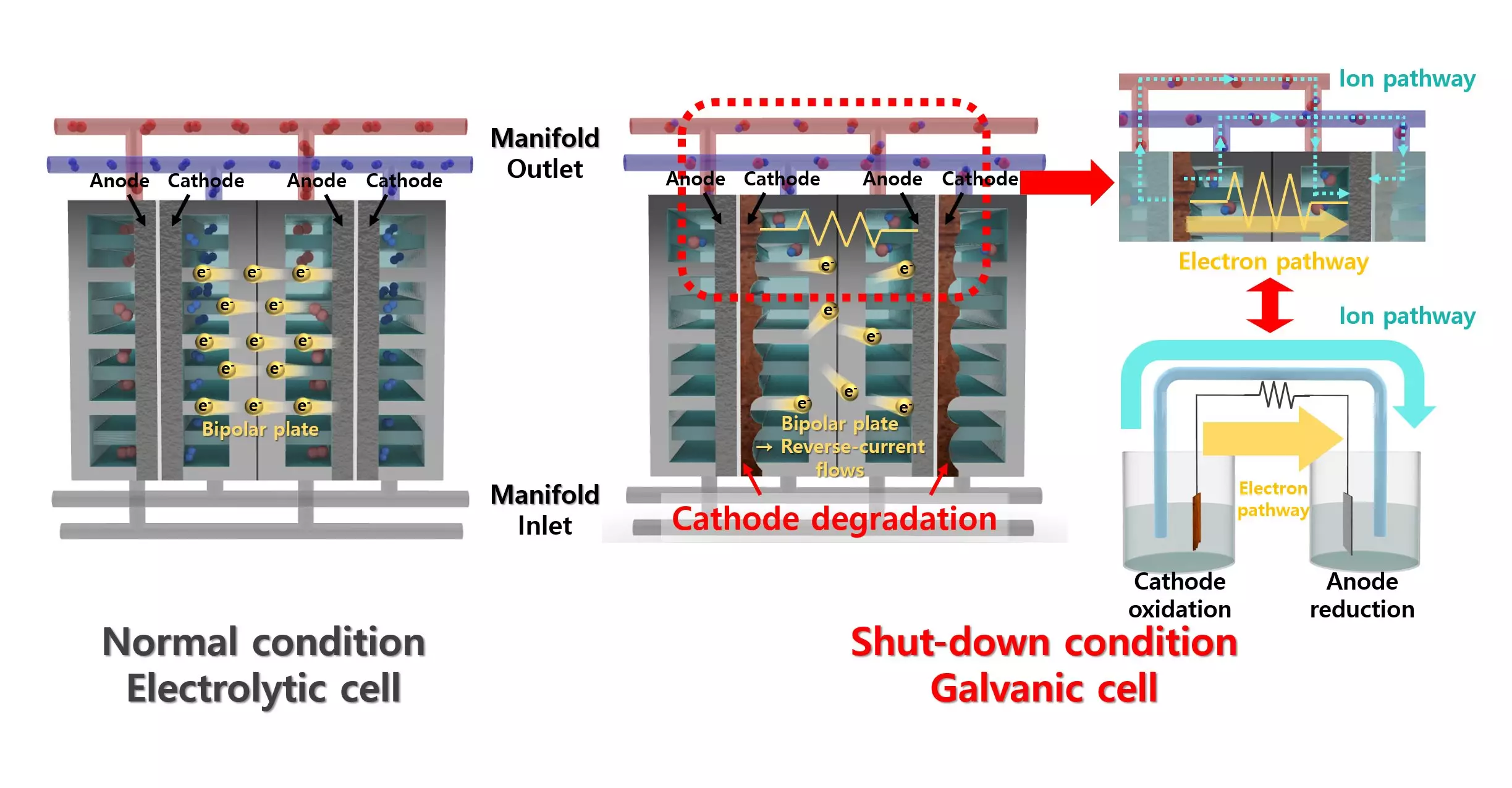

The research centers on a novel approach, utilizing a lead (Pb) coating on nickel (Ni) catalysts—an innovative twist considering lead’s historically low activity in hydrogen evolution reactions. This study highlights how the lead coating acts as a co-catalyst, significantly enhancing the catalytic activity of nickel for the hydrogen evolution reaction. By facilitating key processes such as proton desorption and water dissociation, this combination not only improves efficiency but also offers a solution to a common issue faced by AWEs—the damaging effects of reverse current when the power supply fluctuates.

Strength Under Stress: Durability Against Reverse Current

One of the most exciting aspects of this research is the catalyst’s resilience under operational stress. Past catalytic systems often required additional equipment to mitigate reverse current issues, thus complicating the electrolyzer’s design and increasing costs. In stark contrast, the newly developed lead-coated nickel catalyst performs robustly—demonstrating strong resistance against degradation from repeated start-stop cycles. This key realization could simplify AWE systems, making them more cost-effective and enhancing their reliability, which is essential for incorporating into modern energy infrastructures.

Implications for Future Renewable Energy Systems

The innovation brought forth by this research presents transformative potential not only for hydrogen production but also for the overall landscape of renewable energy systems. By addressing the operational challenges of alkaline water electrolysis with a straightforward solution, this catalyst opens a pathway for broader adoption of hydrogen as an energy carrier. The implications could resonate deeply across various sectors, including transportation, energy storage, and industrial applications, ultimately driving the shift toward a more sustainable future.

In an era where energy security and sustainability are more crucial than ever, advancements like these bring renewed hope for overcoming the inherent challenges posed by renewable energy reliance. As researchers continue to refine and optimize such technologies, the prospect of a hydrogen-powered future becomes increasingly attainable.