For years, the standard perspective in material science has viewed voids or pores as detrimental imperfections that undermine the structural integrity of materials. This conventional belief often leads manufacturers to seek ways to eliminate such flaws entirely, resulting in overly dense materials that may not perform as well as hoped in various applications. Recent research led by Prof. Jin Haijun at the Institute of Metal Research (IMR) of the Chinese Academy of Sciences presents a paradigm shift that recognizes the potential advantages of nanoscale voids, revealing that the strategic introduction of these features can enhance, rather than degrade, mechanical properties.

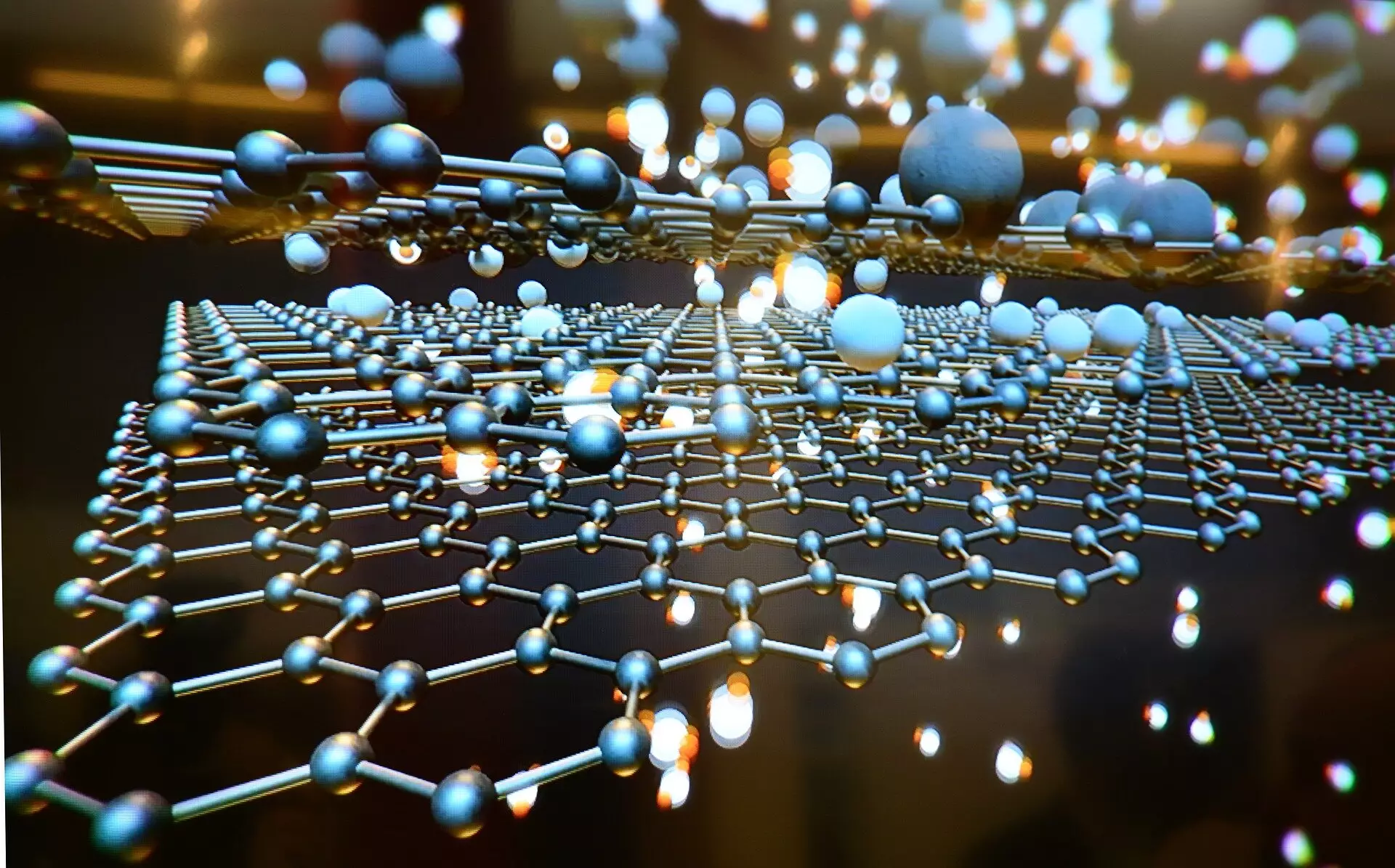

The groundbreaking study documented in *Science* introduces a novel metal known as nanovoid dispersed gold (NVD Au). Unlike traditional gold, which is largely homogeneous and dense, NVD Au incorporates a vast number of nanoscale voids, measuring just a few nanometers up to several hundred nanometers. This unique microstructure is deliberately engineered during the manufacturing process, which includes dealloying, compression, and thermal annealing techniques. The meticulous distribution of these voids throughout the material is what distinguishes NVD Au from its denser counterparts.

The research team observed that NVD Au exhibits remarkable enhancements in both strength and ductility. When subjected to tension tests, this material demonstrated a capability to endure significantly higher loads while also being stretched to greater lengths without rupturing. This contrasts sharply with conventional methods of void introduction, such as powder sintering or additive manufacturing, which typically result in large, irregular voids that compromise material integrity. The underlying explanation for this improved performance lies in the interactions between dislocations and surfaces as well as a reduction in the likelihood of crack formation—factors that are significantly better in the structured environment of NVD Au compared to traditionally manufactured metals.

One of the standout aspects of this research is the inherent sustainability of the NVD Au process. By achieving reinforced strength and reduced density without altering the chemical composition or the fundamental phase of the gold itself, the excellent physical and chemical properties of the base material are largely preserved. Prof. Jin advocates for the versatility of this approach, which holds promise in various sectors, including portable electronics and aviation. In these industries, where both lightweight materials and high performance are crucial, the benefits of adopting NVD Au could be transformative.

This study underscores the importance of collaboration among research institutions, as it involved partnerships with scientists from the Liaoning Academy of Materials and Nanjing University of Science and Technology. Such cooperative efforts are essential for pushing the boundaries of material innovation. By merging insights from multiple disciplines, future advancements can capitalize on these findings to lead to further breakthroughs in material applications.

The progressive work conducted by Prof. Jin and his team heralds a new chapter in material science where nanoscale voids are no longer seen as flaws, but rather as avenues to enhance performance, opening doors to innovative applications across various fields.