The urgency for innovative energy solutions has never been more pronounced. An impending climate crisis, coupled with a global demand for cleaner energy sources, has set the stage for significant advancements in green hydrogen production. Hydrogen, particularly in its green form, which is produced from renewable energy sources, is poised to be a game-changer in the quest for sustainable fuel alternatives. Recent research sheds light on revolutionary techniques for enhancing the efficiency of hydrogen production, crucially advancing towards an eco-friendlier future.

Research published in a leading scientific journal highlights how refining the process of splitting water into hydrogen and oxygen can dramatically reduce costs and increase the feasibility of green hydrogen at an industrial scale. As hydrogen is heralded as a critical component in the United States Department of Energy’s roadmap for achieving net zero carbon emissions, understanding the technological advancements that facilitate its production is key.

Understanding the Mechanics of Electrolysis

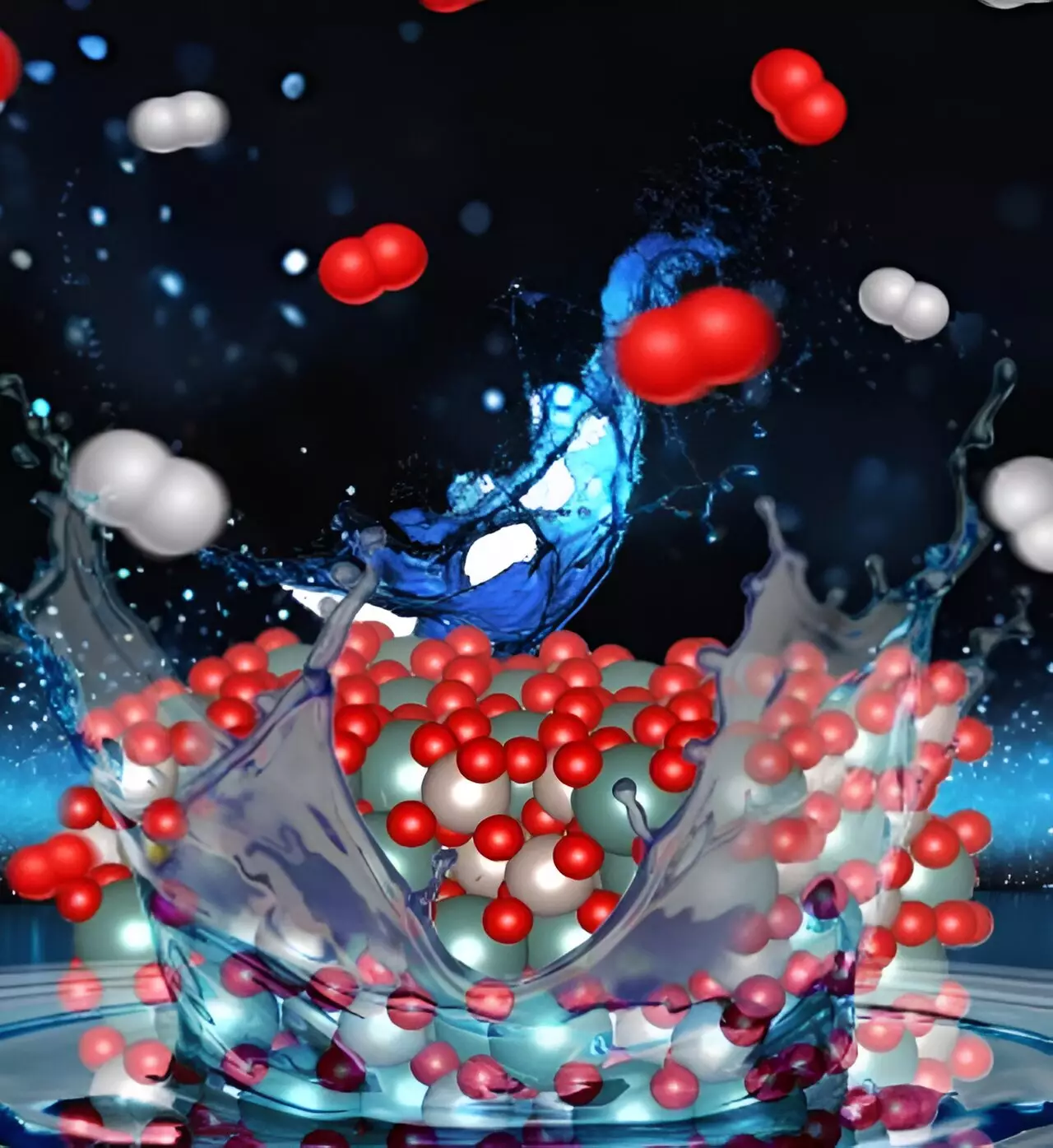

At the heart of green hydrogen production lies the electrolysis process, where electricity is harnessed to separate water molecules into hydrogen and oxygen. Current systems, particularly Proton Exchange Membrane (PEM) electrolyzers, have demonstrated the potential for this transformational energy storage method. However, a significant challenge persists: the rate at which hydrogen can be produced is often limited by the slower generation of oxygen. Essentially, while the cathode efficiently releases hydrogen, the anode lags in producing oxygen.

This bottleneck inhibits the overall efficiency and output of the system, ultimately complicating large-scale adoption of green hydrogen as a viable energy source. The newly reported research aims to address this dilemma through the manipulation of catalytic processes to enhance oxygen production. The study reveals that fine-tuning the properties of a specific complex oxide material can expedite this critical component of the electrolysis process, thereby boosting overall system efficiency.

Defect Engineering: A Novel Approach to Catalysis

Enter defect engineering—a groundbreaking technique that is reshaping the landscape of electrochemistry. Traditional methods often emphasize creating ‘perfect’ catalysts, but researchers led by Professor Hong Yang suggest through their findings that imperfections can, counterintuitively, bolster performance. By introducing specific impurities, such as yttrium into a base material of ruthenium, they have succeeded in optimizing the electrocatalyst’s performance.

This technique mirrors practices found in the semiconductor industry, where subtle alterations to silicon can lead to enhanced functionalities. Professor Yang’s team discovered that altering the electronic configuration of ruthenium by these minor imperfections allows for improved reactivity without increasing the amount of oxygen vacancies present. This nuanced understanding of material science highlights a shift in how we approach catalyst design, where the focus moves away from perfection to a well-balanced system that acknowledges and exploits imperfection.

Empirical Validation and Collaborative Efforts

The study’s methods include comprehensive experimentation to analyze how the new catalysts perform under varying conditions. Insights gained from thermogravimetric analysis—which measures material responses to temperature changes—have enabled the researchers to precisely quantify how changes in composition affect oxygen generation activity. The data presents a compelling case that challenges preconceived notions about material properties and performance outcomes.

Collaboration was central to this research’s success, as it brought together diverse expertise from different scientific disciplines. This interdisciplinary approach underscored the significance of teamwork in tackling complex problems in science and technology. As the researchers navigate various technical hurdles, the pooling of knowledge and skills becomes invaluable, fostering greater innovation and insight.

The Future of Green Hydrogen Technology

As technological advancements continue to emerge from laboratories, there’s hope that these breakthroughs will help realize the full potential of green hydrogen as a reliable energy source. The implications of this research are monumental: achieving efficient and cost-effective hydrogen production stands to revolutionize energy storage, transportation, and overall consumption patterns globally.

One must consider, however, the broader context of these findings. The successful integration of such technologies will depend on more than just scientific ingenuity; it will also require supportive policies, industry buy-in, and substantial investments in infrastructure. In a time marked by escalating climate concerns, the work of these researchers not only pushes the boundaries of materials science but also lays the groundwork for an energy transition that could shape the very fabric of society.

Efforts in this direction, driven by a collaborative spirit and innovative thinking, could indeed spark a transformation—a shift towards a cleaner, more sustainable world powered by green hydrogen.