In the quest for sustainable chemical manufacturing, researchers are continually exploring innovative methods to convert biomass into valuable precursors, particularly olefins. These olefins serve as essential building blocks for a variety of products ranging from plastics to pharmaceuticals. One groundbreaking study conducted by a team from Kyushu University has shown that zeolite Na-ZSM-5, when subjected to microwave heating, can greatly enhance the efficiency of this conversion process. This novel approach not only promotes energy savings but also aligns with the industry’s increasing focus on sustainability.

Traditionally, the process of reforming naphtha is employed to synthesize the precursors needed for complex organic compounds. However, this method is not without its drawbacks. It requires substantial amounts of energy and leads to significant carbon dioxide emissions. Moreover, the high temperature required for catalytic processes often results in coking, which decreases the longevity and efficiency of catalysts. Therefore, there is an urgent need to identify alternative, more ecological methods for synthesizing these essential chemicals.

Cooking oil waste and microalgal oils have emerged as promising alternatives for sourcing the necessary chemicals. These renewable resources can be utilized through catalytic cracking, featuring zeolite as the pivotal catalyst. Yet, the high thermal demands of the catalytic process remain a significant barrier, necessitating temperatures from 500 to 600°C.

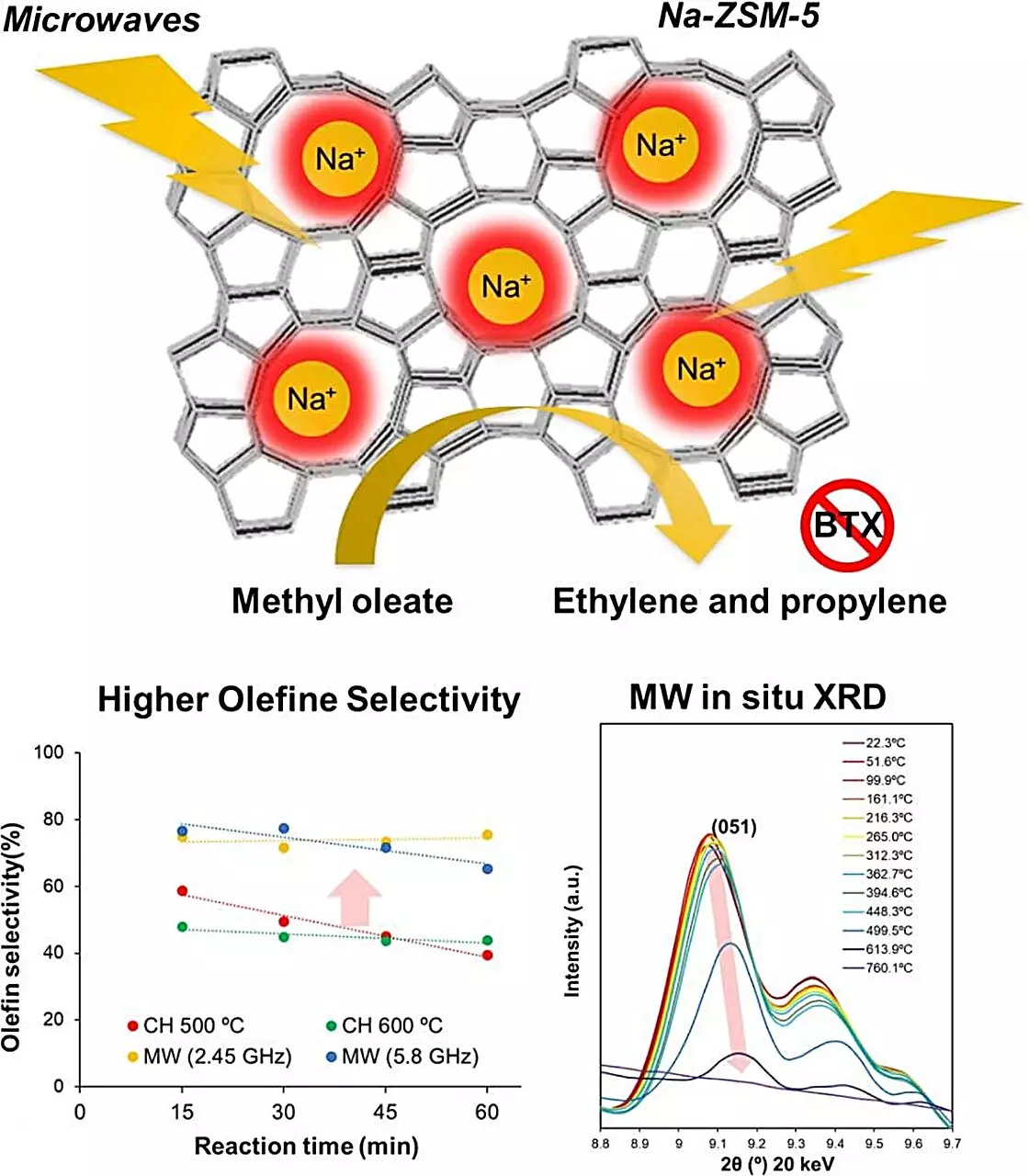

The Kyushu University research team, led by Associate Professor Shuntaro Tsubaki, sought to address these limitations by employing microwave heating to treat zeolite catalysts. Unlike traditional heating methods, microwave energy interacts directly with the materials, providing selective and efficient heating. Tsubaki explains that microwaves can accelerate gas-solid catalysis as they penetrate the gas phase and preferentially heat the solid catalyst, creating localized “hot spots” that drastically enhance the reaction dynamics.

In their study, the researchers meticulously tested a variety of zeolite catalysts to select one that could be effectively heated using microwaves and would demonstrate strong catalytic performance. Their research identified Na-ZSM-5 as the optimal candidate due to its unique properties and compatibility with microwave energy.

To illustrate the practical benefits of microwave heating, the team conducted experiments converting methyl oleate using the selected zeolite catalyst. The results were striking: the Na-ZSM-5 catalyst demonstrated exceptional conversion efficiency, resulting in a remarkable reduction in carbon emissions — CO₂ production was limited to just 1.3% of the total output, and notably, carbon monoxide was entirely absent. The use of microwave heating led to olefin production levels that were four times greater than what was achievable through conventional heating methods.

Furthermore, it was determined that the phenomenon of coking was completely absent when Na-ZSM-5 was exposed to microwave heating, even at elevated temperatures of 600°C. This not only indicates higher catalyst longevity but also showcases the technology’s potential for industrial application.

The researchers delved deeper into the mechanisms behind the microwave heating process, analyzing structural changes in the zeolite lattice. Intriguingly, they discovered localized temperatures exceeding 1000°C within the zeolite’s crystal structure, while the overall material temperature remained stable at 500°C. This disparity suggests that the extreme conditions generated at the micro-scale are crucial for the selective production of olefins, pointing towards an evolution in our understanding of catalytic processes.

The findings from Kyushu University hold significant implications for the future of the chemical manufacturing industry. By utilizing microwaves for catalyst activation, we can achieve critical sustainability goals with reduced environmental impact. The ability to harness renewable energy sources, such as solar and wind, to generate microwaves further emphasizes the potential to revolutionize conventional manufacturing processes.

The researchers aim to build on their initial results by enhancing microwave-driven catalytic processes, striving for improved yields and energy efficiency, and preparing to scale this innovative technology for wider industrial use.

The pioneering work from Kyushu University signifies a promising leap toward transforming biomass conversion and the broader chemical landscape. By adopting microwave technology and zeolite catalysts like Na-ZSM-5, the industry could initiate a powerful shift towards energy efficiency and sustainability. The advancement of these techniques could mark the beginning of a new chapter in chemical manufacturing, minimizing the carbon footprint while maximizing output. The implications for both environmental and economic sustainability could be monumental, setting the stage for a greener future.